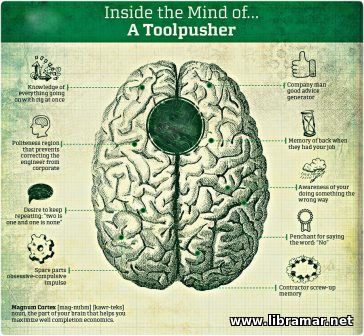

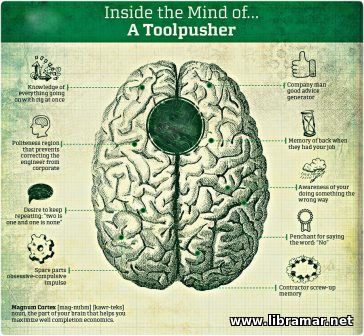

Rig Manager – Toolpusher

The toolpusher’s job has been redefined to include a broader range of responsibilities than formerly; hence the modern title, rig manager. The rig manager reports directly to the drilling superintendent. No longer is the main responsibility simple to get the hole drilled efficiently and quickly. The job has expanded to include direct control over safety, environmental, and other regulatory concerns in the field. The landowner’s concerns over access and water must be addressed. Supply firms must be contacted and supervised. Visitors must be controlled and made aware of safety procedures.

The rig manager makes sure each driller keeps all operations within the rig’s capability and that each driller trains the crew to work safely. Through experience, the hazards on the rig are known and eliminated promptly. If a job safety analysis program is in place, the rig manager has the primary role in its implementation. Periodic inspections are done with each driller’s participation and input. A rig safety list is filled out and the inspection results are reported to the superintendent. The manager investigates every accident, analyzes it with the driller and crew, and oversees needed corrective measures.

Driller

The driller reports directly to the rig manager. The driller is in charge of the rig and crew on the location. From the driller’s console area he or she controls the drawworks and brakes, sets the bit weight, rotary speed, and pump pressure. Experience is important because errors in judgment can lead to damage to the rig or injury to the crew. The rig crew must trust the driller completely because safety depends a great deal on a driller’s skill. A driller must be constantly aware of safety, not only of behavior and actions, but also of each person on the rig. The driller knows the value of teamwork and sees that the crew operates as a well-trained team; knows the ability of each individual; and won’t assign a green hand a job beyond his or her experience.

The driller and the rig manager decide when to pull and change the bit. During active times on the drill floor, such as during a trip or a connection, the driller runs the rig at a pace suited to the crew, knowing that pushing them beyond their ability is dangerous. The driller makes certain that the new crewman knows the job, as well as the safety procedures involved in doing it.

The driller sees that the rig is well-maintained, and trains the crew to be on constant alert for worn or faulty equipment. Once spotted, immediate steps are taken to correct the problem. Drillers make certain all guards, signs, and protective devices are in place and in good condition. A driller must enforce the use of personal safety harnesses by anyone climbing or working overhead. Horseplay is not allowed on the rig. Should a crewman show signs of being under the influence of alcohol or drugs, the driller will relieve him of duty immediately and report the occurrence to the rig manager. The driller keeps all important paperwork current, such as bit performance records, daily reports, and time sheets.

Crew Members

The crew usually consists of a derrickman, two or three floormen and, depending on the rig, a motorman and/or electrician. Each must know the job and function as a team in order to work efficiently and safely.

Each crewman must report to work on time alcohol and drug free. The job demands everyone to be fully alert. Many contractors conduct random drug testing with mandatory testing of the whole crew following an accident. Crewmen must wear personal protective equipment, including proper clothing. Excessive hair length can be hazardous. In some situations beards are forbidden.

On the rig, each crewman must always be safety-conscious. The careful worker learns to be observant, foreseeing danger before harm is done. Some jobs will be repetitive, which can lead to carelessness; that is when the danger increases.

Every crew member should be aware of being struck by or caught between objects, especially around the pipe racks, mud pumps and tanks, and on the rig floor. A rig worker should not engage in unsafe practices. Tools must not be lying around the floor, ladders, or walkways because they present a trip or fall hazard. Crew members should always use the ladders and stairs, and avoid jumping off anything over three feet high. Sliding down rails or riding the catline or elevators must not be done. Very importantly, everyone helps the new crew member by instructing him or her on the correct way to do the job safely and by pointing out the hazards around the rig. A competent crew avoids horseplay and practical jokes that might have serious consequences. Every crew member should be aware of being struck by or caught between objects, especially around the pipe racks, mud pumps and tanks, and on the rig floor. A rig worker should not engage in unsafe practices. Tools must not be lying around the floor, ladders, or walkways because they present a trip or fall hazard. Crew members should always use the ladders and stairs, and avoid jumping off anything over three feet high. Sliding down rails or riding the catline or elevators must not be done. Very importantly, everyone helps the new crew member by instructing him or her on the correct way to do the job safely and by pointing out the hazards around the rig. A competent crew avoids horseplay and practical jokes that might have serious consequences.

Less than five percent of rig accidents are caused by mechanical failure. People make safe operations. It is extremely important for everyone to develop a sense for safety and to practice self-improvement. Before acting, an individual must automatically consider ”will this put anyone in danger?”. Every crew member must be ever alert to risky or unsafe situations. Being alert is the best way to avoid injury to yourself and the crew. It is critical that a new crew member receives supervision and instruction in safe operating procedures immediately upon reporting for work. Industry data show that sixty percent, or more, of rig injuries involve people on the job less than six months. Even the experienced person may need supervision, especially if coming from a different type or size or rig.

Operator

Responsibility for the rig safety follows the corporate chain of command. All are involved; from the operator down to the new floorman.

Depending on the contract, an operator may specify the casing and mud programs to be followed, finish the casing, have it delivered, inspected, and specify the setting depth. If operators furnish the mud, they will control the type and weight and be responsible for having ample supplies on location, or nearby, to control the formation pressures encountered. Such matters are usually covered in the drilling contract. An operator must select a contractor with a rig capable of safely handling the job. The superintendent, field foreman, or consulting drilling engineer may be on location at crucial times and be in direct control of operations. At such times the operator is effectively in charge of seeing that the work is performed without endangering the crew, equipment, or well.

Drilling Contractor or Rig Owner

A contractor has the primary responsibility for safe drilling operations. The rig owner determines the safety policy and instructs  the various supervisors to implement that policy, showing a genuine interest and actively participating in developing all aspects of the company’s safety programs. The rig’s safety record should be as important as performance. A good contractor will never allow cost-cutting measures to compromise crew safety. The contractor has a responsibility to the rig crew and to the client to provide safe drilling equipment. All equipment should be properly sized to safely handle expected load limits, pressures, and depth. All needed safeguards should be in place and meet, or exceed, applicable regulatory standards. the various supervisors to implement that policy, showing a genuine interest and actively participating in developing all aspects of the company’s safety programs. The rig’s safety record should be as important as performance. A good contractor will never allow cost-cutting measures to compromise crew safety. The contractor has a responsibility to the rig crew and to the client to provide safe drilling equipment. All equipment should be properly sized to safely handle expected load limits, pressures, and depth. All needed safeguards should be in place and meet, or exceed, applicable regulatory standards.

The contractor should be aware of, and in compliance with, all governmental regulations pertaining to drilling operations including permit requirements for certain jobs performed by the crew. Responsibility for safety training is given to the drilling superintendent, rig managers, and drillers. They in turn ensure that all personnel under their supervision participate in safety training and education. To underscore their interest in safe operations, some contactors provide safety bonuses, shared by crew and supervisors, after completion of a well.

Most multi-rig contractors have a safety engineer or director charged with the responsibility of overall safety matters. Usually safety personnel report directly to the company president or owner. Should an accident occur, they conduct a thorough investigation, prepare all reports and develop procedures to avoid a reoccurrence of the incident. At the direction of the owner, the safety director may implement a job safety analysis (JSA) program enlisting support and input from all personnel in order to achieve a safe work site.

Drilling Superintendent

Drilling superintendents, or managers, are in top management positions and usually report directly to the owner or company president. A superintendent may be in charge of the overall operations of several rigs, including the performance of the rig managers, drillers, crewmen, subcontractors, service company vendors, and other field personnel. The superintendent is in contact with the operator’s management both before and during drilling, and learns the capabilities of all the rigs and crews under supervision. Other aspects of the job may be to draw up the drilling contact or assure the client that the assigned crew can do the job safely and efficiently.

The superintendent works with the rig managers to see that the equipment and location are rigged up safely. Usual conditions at the locations are dealt with properly. Rig managers are informed on any changes in safety procedures or equipment on the rig and are required to conduct safety training for the crew. Training will include periodic rig inspections meant to spot potentially hazardous conditions and insure that such conditions are eliminated. Rig managers also deal with service companies, consultants, equipment engineers, and others working to improve rig performance and safety. The superintendent works with the rig managers to see that the equipment and location are rigged up safely. Usual conditions at the locations are dealt with properly. Rig managers are informed on any changes in safety procedures or equipment on the rig and are required to conduct safety training for the crew. Training will include periodic rig inspections meant to spot potentially hazardous conditions and insure that such conditions are eliminated. Rig managers also deal with service companies, consultants, equipment engineers, and others working to improve rig performance and safety.

Continued

The captain of the crew boat is in command of the boat together with all passengers on board, and cargo. It is absolutely imperative to follow all instructions! A boat captain has the right to refuse passage to anyone thought to be under the influence of alcohol or drugs, or anyone who appears to be an unsafe passenger for any reason.

Smoking is not allowed in or around the crew boat. Do not smoke! Note that failure to comply with this rule will inevitably have serious consequences. Passengers must ride inside the boat and not on the deck unless there is an emergency or they are specifically authorized to be there.

The disembarking process is potentially hazardous particularly in high winds or rough seas. Wait for the captain to give clearance to exit. Inspect your lifejacket prior to wearing and make sure that it is securely fastened before coming on deck.

Transfer to the platform will be by several ways. In this articles we will touch two classic ways, namely transfer by personnel basket or by swing rope. The modern means of transfer such as the “frog” and Ampelmann transfer will be dealt with in one of the future articles.

In case of a swing rope the transfer should be at the peak of the vessel’s rise. Face the point where the boat is bumping the platform. Use both hands to hold the rope above a knot. Do not hold the rope between the legs. Do not allow feet or legs to be caught between the boat and the platform. Release the rope for the next person and stand clear. Luggage should be transferred separately in the material basket.

In the transfer is by a personnel basket the transfer, stand in the area designated by the captain. Allow enough room for the basket to swing about. When the basket is lowered from the platform, onto the deck, place luggage and other material in the bottom center of the basket. Step onto the outside rim and hold the basket ropes securely. Keep the knees slightly bent in anticipation of sudden, unexpected moves, particularly in rough seas.

After coming onboard, report immediately to the person in charge of the facility and sign in. you will be assigned a bunk and locker, and a duty station. Information about the rig will be provided: emergency signals, communications, first-aid equipment, reporting injuries, escape routes, smoking regulations, wearing work vests or life jackets, overwater transfers, and fire systems. Procedures for reporting any fuel leakage or escaping oil and gas will be explained.

Specific duties in the event of an emergency, fire, or abandonment will be explained. These emergency procedures are normally posted on station bills that will be located throughout the facility. Please take your time and read them carefully to make sure you are duly prepared to perform them if necessary – the proper knowledge and understanding of these instructions may play a vital role in case of an emergency.

Pollution prevention is another aspect considered especially important offshore. Never throw anything overboard. All rules designed to protect the environment should be strictly observed regardless of the geographical region where the offshore transportation is undertaken. Familiarize yourself with the content of the relevant posters.

Of course, the transportation rules and regulations will differ from one country to another, considering the rules and restrictions imposed by the local authorities as well as company policies and many other factors; however, the instructions provided in this short article will apply in most of the cases and, when followed, will significantly contribute to the safety of your voyage. Have a safe trip!

We recommend that you go through the content of this short article carefully as this information can be important when traveling to the offshore installation and back. It covers the very basic principles of safe transfer. Of course, the procedures vary from country to country and also different companies can have their policies in place so you must always adhere to them.

On an offshore rig, safe operating procedures and equipment are similar to those on land. Added safety considerations apply, however, involving transportation by helicopter, working over water, and drills of training for various emergency situations. Statistically, offshore drilling has a better safety record than land.

You must report to the heliport on time. Check in early with the dispatcher to see that each name is on the passenger list. Provide all requested information: name, weight (including baggage), company, and designation. Advise the dispatcher and pilot if any type of authorized hazardous material is being transported. Do not loiter around the dock or heliport area. Remain in the designated passenger area until the pilot or captain has given clearance to board. Never attempt to take alcohol, drugs, firearms, explosives, or flammables onto an offshore installation.

The pilot is in total command of the helicopter, passengers, and cargo. Follow instructions! A pilot can refuse passage to anyone thought to be unde r the influence of alcohol or drugs, or anyone who appears to be an unsafe passenger for any reason. r the influence of alcohol or drugs, or anyone who appears to be an unsafe passenger for any reason.

Hold lightweight articles like hats, jackets, or raincoats firmly to prevent their being sucked into the rotors. Carry long articles parallel to the deck, keeping them clear of the rotor blades.

Approach and depart aircraft from the front. Walk briskly but do not run. Avoid the area of the tail rotor and boom at all times. Approach or depart the helicopter in a crouched position, keeping will below the rotor tips. Be especially wary in high winds when the rotor blades may dip below six feet.

Do not store luggage until the pilot gives you instructions. This is important as wrongly stowed luggage can become an obstacle when leaving the helicopter in emergency.

When boarding or departing, step carefully on the proper footholds to avoid damage to the craft’s floats. Do not jump!

The pilot is concerned with load distribution; store baggage according to instructions and take the assigned seat. Fasten the seat belt and keep it fastened until told it is safe to remove it. The pilot is concerned with load distribution; store baggage according to instructions and take the assigned seat. Fasten the seat belt and keep it fastened until told it is safe to remove it.

Inflatable life jackets should be worn during all over-water flights. Return the jacket to the storage area before departing the aircraft.

Before takeoff, each person should note the closest emergency exits, inflatable life rafts, fire extinguishers, or other emergency equipment. Advise the pilot of any problems with the equipment at once. Pay attention to the pilot’s preflight emergency briefing and follow instructions should an emergency occur.

Smoking is not allowed in or around the aircraft at any time.

Never throw anything from the helicopter. This could result in damage to the rotors and is absolutely forbidden at all times.

If hearing devices are provided, wear them as needed or instructed, to prevent any harm to the ears.

In an emergency situation remain in the seat with seatbelt fastened. Do not attempt to jump from the craft; await the pilot’s instructions. Do not inflate a life jacket or the inflatable life raft inside the cabin. Such action would hinder, or possibly prevent, a speedy, safe evacuation.

In this article we have covered the safety precautions to be taken when you travel offshore by the helicopter. However, and quite frequently, the transportation is done by means of the crew boat. Our next article will concentrate on what you shall do when traveling by boat.

|

Every crew member should be aware of being struck by or caught between objects, especially around the pipe racks, mud pumps and tanks, and on the rig floor. A rig worker should not engage in unsafe practices. Tools must not be lying around the floor, ladders, or walkways because they present a trip or fall hazard. Crew members should always use the ladders and stairs, and avoid jumping off anything over three feet high. Sliding down rails or riding the catline or elevators must not be done. Very importantly, everyone helps the new crew member by instructing him or her on the correct way to do the job safely and by pointing out the hazards around the rig. A competent crew avoids horseplay and practical jokes that might have serious consequences.

Every crew member should be aware of being struck by or caught between objects, especially around the pipe racks, mud pumps and tanks, and on the rig floor. A rig worker should not engage in unsafe practices. Tools must not be lying around the floor, ladders, or walkways because they present a trip or fall hazard. Crew members should always use the ladders and stairs, and avoid jumping off anything over three feet high. Sliding down rails or riding the catline or elevators must not be done. Very importantly, everyone helps the new crew member by instructing him or her on the correct way to do the job safely and by pointing out the hazards around the rig. A competent crew avoids horseplay and practical jokes that might have serious consequences.

the various supervisors to implement that policy, showing a genuine interest and actively participating in developing all aspects of the company’s safety programs. The rig’s safety record should be as important as performance. A good contractor will never allow cost-cutting measures to compromise crew safety. The contractor has a responsibility to the rig crew and to the client to provide safe drilling equipment. All equipment should be properly sized to safely handle expected load limits, pressures, and depth. All needed safeguards should be in place and meet, or exceed, applicable regulatory standards.

the various supervisors to implement that policy, showing a genuine interest and actively participating in developing all aspects of the company’s safety programs. The rig’s safety record should be as important as performance. A good contractor will never allow cost-cutting measures to compromise crew safety. The contractor has a responsibility to the rig crew and to the client to provide safe drilling equipment. All equipment should be properly sized to safely handle expected load limits, pressures, and depth. All needed safeguards should be in place and meet, or exceed, applicable regulatory standards. The superintendent works with the rig managers to see that the equipment and location are rigged up safely. Usual conditions at the locations are dealt with properly. Rig managers are informed on any changes in safety procedures or equipment on the rig and are required to conduct safety training for the crew. Training will include periodic rig inspections meant to spot potentially hazardous conditions and insure that such conditions are eliminated. Rig managers also deal with service companies, consultants, equipment engineers, and others working to improve rig performance and safety.

The superintendent works with the rig managers to see that the equipment and location are rigged up safely. Usual conditions at the locations are dealt with properly. Rig managers are informed on any changes in safety procedures or equipment on the rig and are required to conduct safety training for the crew. Training will include periodic rig inspections meant to spot potentially hazardous conditions and insure that such conditions are eliminated. Rig managers also deal with service companies, consultants, equipment engineers, and others working to improve rig performance and safety.

r the influence of alcohol or drugs, or anyone who appears to be an unsafe passenger for any reason.

r the influence of alcohol or drugs, or anyone who appears to be an unsafe passenger for any reason. The pilot is concerned with load distribution; store baggage according to instructions and take the assigned seat. Fasten the seat belt and keep it fastened until told it is safe to remove it.

The pilot is concerned with load distribution; store baggage according to instructions and take the assigned seat. Fasten the seat belt and keep it fastened until told it is safe to remove it.