When establishing an oil or gas well, it is not enough just to drill a hole from the surface down to the hydrocarbon layer. The hole must be cased with steel pipes that are duly cemented to the formation in order to make sure than no undesirable event, such as formation fluids entering the hole, and causing blowout take place in the process of drilling. This is one of the key aspects of all drilling programs.

It is very important for anyone engaged in the drilling process to have clear and deep understanding of the casing, what it consists of and how it functions. This is what we have tried to cover below in this mini-article. You are highly encouraged to go through the listing carefully and make sure equal attention is given to each item.

These casings have several important functions of which the following can be named:

• To prevent the hole being washed out in weak formations or collapsing.

• Prevent lost circulation.

• Control the formation pressure, where the density of the drilling fluid (mud) is not heavy enough to control the formation pressure. This can be the case, if one has just drilled through a high pressure zone, set a casing and after that have reduced the mud weight to drill the next type of formation.

• Control the production from the oil / gas bearing formation.

• Prevent water from entering the production zone.

• Make the installation of tubing possible, and production test equipment and other equipment that is necessary to achieve an effective production (seals, pumps etc.).

• Isolate the mud and the hole wall mechanically from each other to prevent fluid loss from the mud to the formation.

prevent fluid loss from the mud to the formation.

• Reduce the friction forces that are present. Especially important with directional drilling.

• Function as a foundation for the BOP and thereby make pressure control possible.

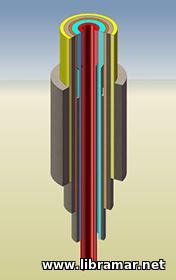

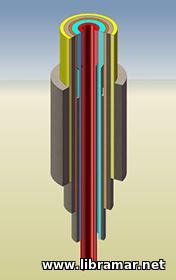

Casing are named after the different tasks they have to perform, here they are named in the order they are inserted:

• Surface casing.

• Intermediate casing.

• Production casing.

• Liner.

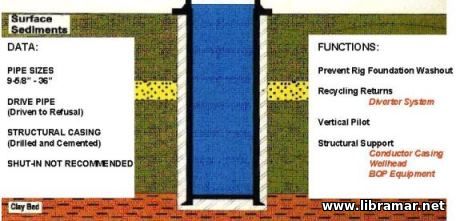

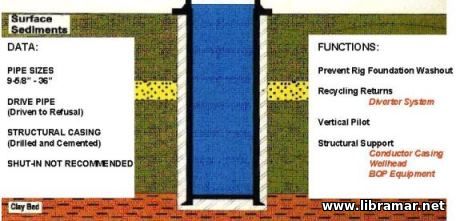

Conductor pipe

Conductor is the first casing. It is often a 30’’ pipe placed in a 36’’ hole at a depth of 150 feet to 500 feet under the seabed. With jack up rigs it is often hammered in and is also called a drive pipe.

The purpose of this casing is to ensure the return of the drilling fluid, while at the same time prevent the loose formations on and below the seabed in collapsing into the hole. It is also the foundation of the permanent casing frame when drilling from a floating rig, and is often constructed with extra wall thickness in the top.

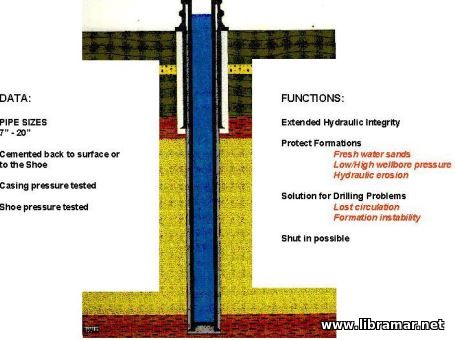

Surface casing

Surface casing can be a 20’’ pipe placed in a 26’’ hole at a depth of from 1000 feet to 3000 feet, depending on local conditions. This should line the hole down to a depth where the formations are enough compacted and strong enough to exert the necessary forces, if a BOP is closed in connection with pressure control, as the casing is the foundation for the BOP.

The casing should reach down to a formation that is sufficiently strong to hold the pressure from a drilling fluid, with sufficient density to control the formation pressure down the next casings setting depth. The surface casing should also isolate possible shallow pockets of gas.

The casing should reach down to a formation that is sufficiently strong to hold the pressure from a drilling fluid, with sufficient density to control the formation pressure down the next casings setting depth. The surface casing should also isolate possible shallow pockets of gas.

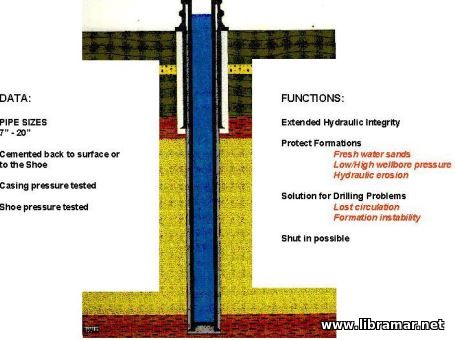

Intermediate Casing

Intermediate casing can be 16’’ pipe, but it is often a 13-3/8’’ and a 9-5/8’’ pipe with setting depths down to 11.000 feet or more, but all depending of weights. The more intermediate casings there are, the less the internal diameter of the last set. This will result in a reduced production rate from the well. Intermediate casings are set to isolate weaker formations, so the formation pressures further down can be controlled with an increased drilling fluid density. In addition they must cover the pressure difference between the formation strength and the formation pressure, which are necessary to control a possible kick with a closed BOP.

When drilling directional, drill string can cause serious damage on the casing. A smaller diameter casing can be necessary in a production well, just before a change in direction, as it will be easier to get a thinner pipe through the bent part of the hole. In certain cases, the casing is not going right up the surface, but is hanged off with the help of a casing-hanger, 100 - 300 feet up in the previously set casing. This is because of economic reasons. This casing is called a liner. If the liner afterwards is connected up to the surface, then a connection can be made with a so-called Tie back assembly

cases, the casing is not going right up the surface, but is hanged off with the help of a casing-hanger, 100 - 300 feet up in the previously set casing. This is because of economic reasons. This casing is called a liner. If the liner afterwards is connected up to the surface, then a connection can be made with a so-called Tie back assembly

Production casing

Production casing is the last set casing. This comes from the reservoir and up to the well head, but in, some cases it is hanged off in the last intermediate casing and is called the production liner.

The production casing should form a sealed connection between the reservoir and the wellhead, and protect the production equipment against pollution from outside, and make it possible to control the well, when the production assembly is retrieved for work over etc. The production casing forms a barrier between reservoir and the production equipment, so the reservoir fluid can be controlled through the perforations and possible gravel or sand packing.

prevent fluid loss from the mud to the formation.

prevent fluid loss from the mud to the formation. The casing should reach down to a formation that is sufficiently strong to hold the pressure from a drilling fluid, with sufficient density to control the formation pressure down the next casings setting depth. The surface casing should also isolate possible shallow pockets of gas.

The casing should reach down to a formation that is sufficiently strong to hold the pressure from a drilling fluid, with sufficient density to control the formation pressure down the next casings setting depth. The surface casing should also isolate possible shallow pockets of gas. cases, the casing is not going right up the surface, but is hanged off with the help of a casing-hanger, 100 - 300 feet up in the previously set casing. This is because of economic reasons. This casing is called a liner. If the liner afterwards is connected up to the surface, then a connection can be made with a so-called Tie back assembly

cases, the casing is not going right up the surface, but is hanged off with the help of a casing-hanger, 100 - 300 feet up in the previously set casing. This is because of economic reasons. This casing is called a liner. If the liner afterwards is connected up to the surface, then a connection can be made with a so-called Tie back assembly