The present publication officially released by the American Welding Society, i.e. AWS, is a glossary of the technical terms that are normally used in the welding industry. The purpose of this standard is to establish standard welding terminology to aid during the communication of the relevant welding information. Taking into account that it has been originally intended to serve as a compilation of the welding terms as well as non-standard items in common use.

The terms included in the volume have been arranged in alphabetical sequence. The document defines nearly 1400 welding terms supplemented with almost sixty informative illustrations supporting and clarifying the definitions. In addition to that, the standard includes classification charts together with the corollary information associated with the various welding processes.

All of the terms contained have been prior approved by the AWS; note that this does not apply to the non-standard terms. The decision was made by the authors not to include trademark names and proprietary brands, following the official AWS policy, it means that only generic terminology and definitions have been included. A must-have standard for any person dealing with welding in any way.

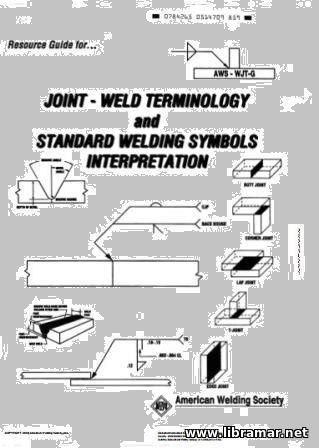

The determination and clear understanding of the design and selection of the weld joints is one of the integral parts of the responsibility of any project engineer, and same equally applies to the welding specifications. But it is still welding personnel who are held responsible for the accurate interpretation of the specification and preparation, assembly and joining of all the components at the various construction phases.

Therefore, the sound knowledge of the weld joints together with the associated symbols, abbreviations and terminology is considered essential for the above mentioned people, since the correct interpretation and application of the terms makes it easier to solve the various fit-up and design problems normally encountered on the daily basis. The present training resource has been designed specifically to give all students and practicing welding engineers with a proper means to get better understanding.

Which, when properly used, will bring them required technical knowledge and skills to be added to their professional toolkit. In turn, professional welders will find it practical and useful when used to improve their job communication and also interpretation of the welding-related information they read from the drawings.

The content of this European Standard was developed by the specialists of the Technical Committee "Environmental Management" no. IO/TC 207 and has subsequently been given a status of the national standard. The main purpose of the standard is to provide all organizations with a framework to achieve better protection of the environments and to properly respond to the environmental conditions keeping due balance with the current socio-economic demands. The document is specifying all applicable requirements enabling organizations to achieve the desired outcomes set for their EMS, standing for the environmental management systems.

The systematic approach applied to the environmental management will provide the management with all required information used to build overall success and also create different options to contribute to the development by means of protection of the environment, mitigating potential effects, providing assistance to the organizations in meeting compliance related obligations, getting the environmental performance enhanced.

This would also include control of the design of the products and services of particular organization and influence them, achieving various operational and financial benefits, communicating related information to the interested parties etc.

The present API Specification is intended to provide the coverage of the minimum technical requirements applicable to the design, fabrication and subsequent testing of the oil and gas separators of oil-field type as well as of the oil-gas-water separators; the content of the document covers the vertical and spherical separators as well as the single/double barrel separators.

The volume starts with the introduction where the scope of the Specification is outlined and some general information is given, which is necessary for understanding of the rest. The definitions used throughout the document have been provided in the same section. The next chapter of the Specification is dealing with the materials, their proper selection and associated corrosion consideration. Then a chapter comes fully devoted to the design of the separators and covering their sizing, temperature/pressure ratings etc.

Sample calculation is also provided in this chapter. The rest of the chapters address marking including API and ASME Code nameplates and stamping, inspection and rejection issues including ASME inspection. Six annexes to the main content supplement it providing corrosion guidelines and process considerations, calculations, design information etc

The American National Standard officially provides all applicable requirements to the dry seal pipe threads. Subject threads are based on the American pipe thread but they significantly differ from USA pipe thread because they are commonly designed to seal the pressure tight joints without having top use additional sealing components. In order to accomplish this purpose, some modification shall be made to the form of the thread and greater manufacturing accuracy shall be reached.

The roots of the internal and external threads truncate more than crests so their flats are slightly wider than crests. This results in the metal to metal contact occurring at the roots and crests either at the time of flank contact or prior to that... This document addresses different types of threads, notations and designations, applications, assembly limitations, tolerances and forms, basic dimensions of the threads and many other information and data.

Three appendices deal with the symbols and formulas, suggested tap drill sizes, specific pipe threads such as special and special-extra short and others. Data tables at the end of the standard provide additional information on basic dimensions, recommended assembly limitations etc.

The present guide developed by ASTM was released to cover the technical information necessary for the development/implementation of the inspection process as applicable to marine ships. The publication will provide required considerations for the people who are interested in making proper structural survey plans for marine ships, and are dealing with planning as well as organizing of the surveys, especially at the design phase of the shipbuilding process. This book may easily be used together with any other regulatory document; however, it may also serve as the technical basis for planning these surveys and their implementation of the survey plans in case no other applicable requirements are available.

The standard provides all interested parties, i.e. vessel owners, construction yards, operators and designers with a plan to develop the inspection process covering all phases of the operational life of the ship - such plan may be developed and implemented in concept with Class of Flag State inspections. In addition to that, the guide will be helpful when used as the basis for the development of the CAP (corrective action plan) for typical deviations and/of deficiencies related to the ship's structure. Note that the safety aspects have not been addressed in the document and remain the responsibility of the involved parties.

The present standard specification ASTM F1511-04 covers the mechanical end-face seals for the positive displacement and centrifugal shipboard pumps. It does not, however, address some types of the seals as follows - oil and lip seals, labyrinth or circumferential types of seals. The values stated within the document are in standard inch-pound units. The SI units have been provided for info only in parentheses. The Appendix S1 to this standard specification contains the special requirements for the United States Navy Shipboard Pump Applications. Within the present document, seals are classified by their type, class and grade.

The categories have been divided according to the application arrangement in the equipment in which thee seals are installed. Talking about the materials, the mechanical seals addressed in this standard publication, must be manufactured using the materials selected from the Tables 1-3 of this standard specification, with all parts being subject to review of the pressure/velocity, temperature and corrosion resistance. The publication will be useful for the crew members dealing with the ordering and installation of subject seals as it provides quite clear reference.

The declared principal intention of this standard guide was to depict the recommended practices relating to the design of vessel's structural details. We all clearly understand the huge importance of the structural details - their fabrication and layout play significant role in making the costs for the hull construction, the details may often be the source of various failures like fractures that could easily lead to the damage of the ship's hull; another important aspect of the problem in question is that the analysis of hull structural details have been neglected by the researchers so far. It should also be noted that today's trends towards decreasing the scantlings of the vessel's hull may also increase the potential of the damage happening to the details.

Taking into account the noted lack of the analytical and experimental efforts to the research of the problems touching the structural details, the determination in this case was left solely to the designers/draftsmen with little to no input from engineering side. This publication gives a recommended listing of the structural details to be used when constructing the vessel - this listing list includes the details that have already failed in service and are therefore not recommended for any further use.

|