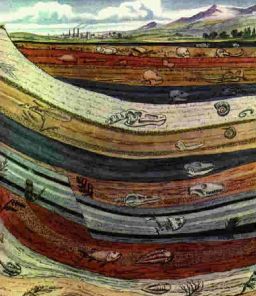

Sometimes a sedimentary basin is uplifted so that deposition ceases and erosion takes over. An erosion surface is formed; the upper surface of the most recent sediment layer, formerly smooth and horizontal, is modified by running water or other agents.

Later, the region subsides and more sediment accumulates. If the succession of sedimentary layers is thought of as a chronological record, then the buried erosion surface represents a time gap of indeterminate length. Such a gap is called an unconformity.

There are several kinds of unconformity. If the uplift is gentle, so that the rock layers are not tilted or deformed, the gap in the geologic record is termed as disconformities. Although the layers of sediment above are parallel with those below, the shapes of ancient stream channels are often apparent in disconformities. However, the disconformities itself may be parallel with the layers above and below and therefore not readily apparent.

Deposition of sediments on layers that have been deformed and eroded produces an angular unconformity. Sedimentary layers below such nonconformity are not parallel with those above, and the gap in the record is obvious.

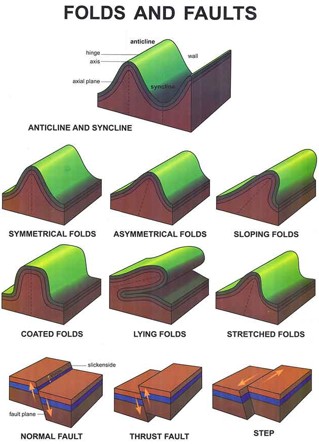

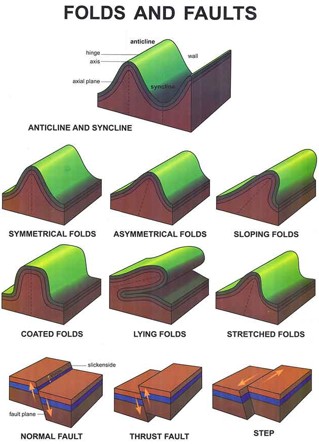

Tectonic plate motion is one of the events that can change the shape and orientation of sedimentary rock layers. Wherever plates converge, the crust is subjected to enormous horizontal forces that can gradually compress it by dozens or even hundreds of miles, wrinkling and folding it like a giant throw rug. The up fold of the crust is an anticline; each down fold is a syncline.

Anticlines and synclines are graphic proof that solid rock can flow like the ice in a glacier. Like most solid materials, rock is slightly plastic under uniform pressure over long periods, it will bend without breaking. However, if stress is applied unevenly or if it exceeds the rock's breaking strength, the rock fractures. A fracture in the crust along which the rocks on opposite sides have shifted relative to each other is termed a fault.

A normal fault is one whose slip plane is at a steep angle with the surface and along which the rock on the upper side has slipped downward in the direction of the dip. In geology, the dip of any surface is the direction in which a marble would roll if placed on it.

A reverse or thrust, fault is one in which the rock on the upper side has been displaced upward along the fault plane. A normal fault allows extension of the crust; it is often caused by forces that stretch the crust. A thrust fault is caused by forces that squeeze the crust together, causing a break where one piece overrides another.

An over-thrust fault is a thrust fault whose slip plane is nearly horizontal its displacement is the result of large horizontal movements of the crust. Along some over-thrust faults, one slab has slipped several miles over the top of another so that a well drilled through the fault would penetrate the same series of rock layers twice.

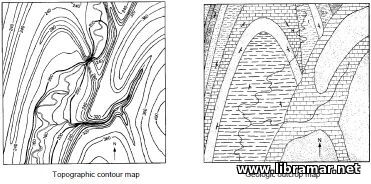

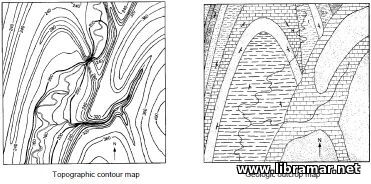

As geologists gather information about the structure and character of the rock formations, they arrange it in graphic form. This not only helps them visualize what they cannot see directly, but also provides a way to communicate their findings to others. In particular, it helps them visualize and display the stratigraphy of the crust-information that describes the origin, composition, distribution, and succession of rock layers.

Maps, Sections, and Diagrams

Geologic information can be arranged graphically to show variation either horizontally or vertically. Horizontally arrayed data are maps; vertically arrayed data are sections. Sometimes these two types of arrays are combined in a simulated three-dimensional graph.

A geologist usually starts with a base map of the area of interest, showing survey benchmarks, property lines, and such non geologic surface features as streams, roads, and buildings. Base maps are useful for planning exploration, leasing, road building, well placement, and other activities. geologic surface features as streams, roads, and buildings. Base maps are useful for planning exploration, leasing, road building, well placement, and other activities.

Each depositional environment has its characteristic assemblage of sedimentary rock types. When discussing these types, it is convenient to think in terms of three basic types: clastics, carbonates, and evaporates. Note, however, that any rock is likely to have characteristics of more than one of these types.

Clastics

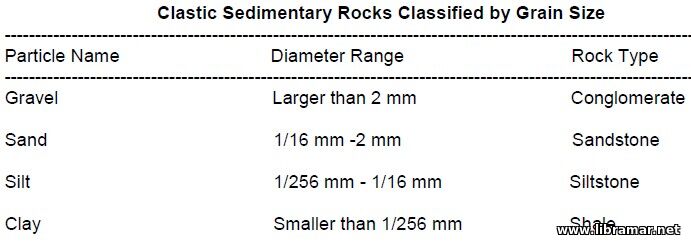

Clastic sedimentary rocks are composed mostly of particles derived from other rocks. There are two basic types of clastic particles: mineral grains, composed entirely of a single mineral, such as quartz, feldspar, or mica; and lithic grains, which consist of an assemblage of different minerals, like miniature rocks. In rocks with clastic texture, the grains touch each other but do not interlock. The crystalline texture of igneous rock, by contrast, is characterized by mineral grains that are in contact on all surfaces, having formed and grown together as the rock solidified. Sedimentary rock usually has empty (or fluid-filled) spaces between grains.

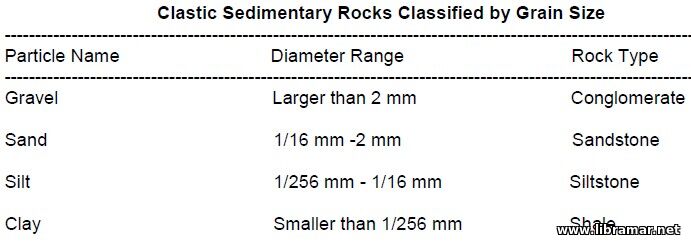

Clastic rocks are classified primarily by grain size. They are named according to the size of the particles that make up more than 50 percent of their bulk. A rock composed of 60 percent sand and 40 percent calcite, for example, would be called limy sandstone.

For the petroleum geologist, sedimentary rock is the most interesting type of rock. Some sedimentary rock formations are porous enough to hold great quantities of oil and gas; others contain high proportions of the organic matter from which, under certain conditions, hydrocarbons are generated.

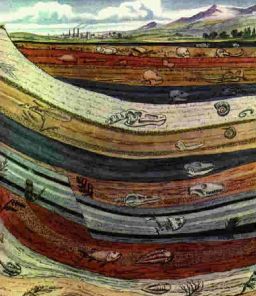

Sedimentary rock is rock made up of fragments or chemical compounds from previously existing rocks or organisms. Carried by flowing water, ice, or air in response to the force of gravity, sediment accumulates in upland basins and along the edges of the continents. The depth of an accumulation can reach several miles. Deeply buried sediments are transformed into hardened rock by a set of processes called, collectively, lithification. The processes that alter the rock itself, either during or after its formation, are called diagenesis.

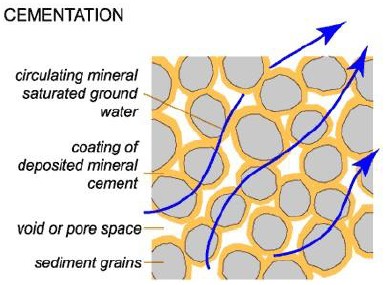

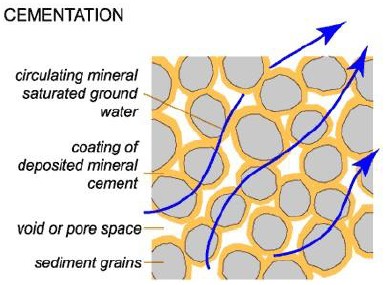

Compaction and cementation are two of the principal processes that change sediments into rock. As successive layers of water-saturated sediment accumulate, the deeper layers are compacted by the weight of overlying beds. The individual grains are forced into closer contact and, in some cases, are deformed. Minerals dissolved in the water-commonly, calcite form a solid material that cements the grains together. Much of the water is squeezed out as the sediment is transformed into rock, but some becomes trapped in the pores as connate, or interstitial, water. Rock formed from sediments deposited by water almost always contains interstitial water. rock. As successive layers of water-saturated sediment accumulate, the deeper layers are compacted by the weight of overlying beds. The individual grains are forced into closer contact and, in some cases, are deformed. Minerals dissolved in the water-commonly, calcite form a solid material that cements the grains together. Much of the water is squeezed out as the sediment is transformed into rock, but some becomes trapped in the pores as connate, or interstitial, water. Rock formed from sediments deposited by water almost always contains interstitial water.

Close study of sedimentary rock reveals the conditions under which it was formed. One set of conditions includes the events that occur beneath the surface during lithification and diagenesis compaction, cementation, and chemical alteration by groundwater. The natural conditions that most influence the character of sedimentary rock are, however, those that occur at the earth's surface, where the solid earth is in contact with the fluids of the atmosphere and the oceans and where plants and animals live. The set of physical, chemical, biological, and geologic conditions under which the original sediments of a given rock layer were laid down are called the depositional environment.

Jack-up drilling rigs are built as drilling platforms with jack-able legs. The platform will float when the legs are retracted and can thus be moved around the world on water. The jack-up rig is one of the most versatile rig designs available. The largest jack-up type rigs can work in water depths up to 150 meter and can also work in very shallow water depths. Among the many advantages of the jack-up rig is the fact that as soon as it is jacked up and into drilling position, it is a very stable platform and does not need motion compensation of any sort as required by a floating rig type.

Most jack-up designs today consist of a triangular hull with one leg in each corner. The hull is several floors high (thick) and contains most of the “indoor” equipment required to make the rig work. Indoor equipment includes generator sets, mud pumps, mud mixing and cleaning systems, bulk stores, mud tanks, water and fuel tanks as well as all the systems required for a hotel with accommodation for at least 100 people.

Attached to the top of the hull is first and foremost the living quarters and offices; on relatively old oil rigs, these can still be located below deck level, but this is not allowed anymore). Also on the topside is the drilling package itself, often contained on a cantilevered skid which enables the drilling package to center itself over different slots or wells. The rig is often used to drill production wells from templates or jackets with many well slots and for this reason is required to be able to crisscross over a grid of well heads.

The drilling package is located between two of the corners and positioned in such a way that the drilling package is stable and has maximum load bearing capability. a way that the drilling package is stable and has maximum load bearing capability.

The legs on a jack-up rig are special. They not only have to withstand and be able to lift the entire weight of the rig, the legs also have to resist twisting forces and high wind loads as well.

Modern Jack-up legs are often triangular in shape and have something called a spud can mounted on bottom of each leg. The spud can is a large dome shaped tank and is working as the foot of the leg absorbing weight of the rig and due to its large area prevents high leg penetration into the seabed.

Let us spend a couple of minutes on the land-based oil rigs. Yes, most of the materials and information presented herein are related to the offshore units; however, it would make sense to know a bit about how this all started. Just read this short article.

As we know, the very first drilling rigs used were land rigs and were invented and subsequently both in Texas, USA and in Germany just over hundred years ago.

Nowadays, the land-based oil rigs constitute an advanced piece of machinery and when thinking of the amount of engineering and care in manufacturing, racing cars can look a bit sedate.

Land rigs come in all sizes, from small trailer mounted rigs to very large rig systems requiring more than 100 trucks to move. One of the first criteria for design of a land rig is how to move it. If the rig has to move on normal roads, it has to be dismantled to pieces that can be easily be transported by truck and does not exceed axle load restrictions.

In addition to weight limitations, the sizes of equipment that has to be moved will also impose problems and cost. In most countries, there are rules for height and width of goods to be transported on roads. When exceeding these rules, police escort and road and bridge modifications may add significantly to the overall cost of drilling a well.

Rigs dedicated for work in deserts are quite often built without regards for road transport. Some of the EDC, standing for the Egyptian Drilling Company, rigs working in Syria and in Egypt have large wheel assemblies, or moving gears retrofitted so the entire Rig with mast and substructure can move in one piece.

This is quite a reduction in loads to move and makes quite a difference in the time it takes to move the rig. If it takes seven days to move a rig without the moving gear attached it will take approximate sixty hours for the rig move with the moving gear attached. This is quite a reduction in loads to move and makes quite a difference in the time it takes to move the rig. If it takes seven days to move a rig without the moving gear attached it will take approximate sixty hours for the rig move with the moving gear attached.

Land rigs have a distinct advantage over rigs made for working on water, space and weight is not a problem. Contractors build rig sites to suit the rig and the equipment not the other way around. A standard desert foot print for a rig location is 400 ft x 400 ft.

Another advantage is that if a project requires special equipment this can be added to the rig inventory without worrying about deck loads and permissions. Also, note that a rig may require additional mud tanks for a well and this will then be no problem as land locations can be expanded easily enough.

Newer land rigs are also designed for fast rig up and rig down as well as minimizing the impact on the landscape and environment. Drive past a pad of producing wells today and there will hardly be anything to evidence that a big rig and a large rig location has been in use. All that can be seen is a few square meters of concrete where the wellhead is located and safely fenced in.

Although this section of our website is devoted to the offshore exploration and drilling activities, this short article is here to cover the major types of oil rigs in general.

Oilfield drilling is, when it comes down to bare essentials, a question of “drilling a usable hole” in the ground. And, in turn, usable hole is commonly characterized by being a hole in the ground that lives up to the requirements of the well-plan and includes benchmarks for production, cost and lifespan.

The main pieces of equipment required to drill a hole in the ground is collectively known as a drilling rig. Drilling rigs are classified according to what the rig is supposed to be standing on when it drills and how it is moved around. The main media to stand on is land and water.

It is pretty simple, but that is how it is.

Land rigs are made for working on solid ground where no special requirements are necessary except the area to be flat and of a certain size. All other rigs are made for working either over water or floating in the water. There are barges and jack-up type rigs which are made to stand on the seabed on the bottom of the water and/or swampland and marshes, and there are semi submersibles and drill ships that float in the water. Each type will be described separately on the next pages. It is important to notice that in general, the main drilling equipment on all these rigs are the same. The difference is how it moves and where the drilling location is situated.

There are other sub-types of drilling rigs that are not specifically described here. These rig types include:

• Heli-Rigs, or Helicopter transportable land rigs, these are made mostly of aluminum,

• Dedicated coiled tubing rigs,

• Slanted drilling rigs, used for the Slant hole drilling ,

• HDD, utility drilling rigs, normally hydraulic-driven.,

Most of them use the same type of equipment to drill and most of the processes are very similar with the exception of coiled tubing drilling systems.

In this lecture on drilling equipment, the focus will be put on the drilling rig and its related equipment. The method of drilling the hole is subject for a different lesson.

Some types of equipment are used on all types of rigs, basically the drilling equipment, and other equipment is rig type-specific, i.e., to be able to compensate problems inherent in the rig design or use.

When looking at different drilling rig types and different locations around the world, all drilling rigs consist of the same basic equipment with the same functions, all over the world. A giant concrete platform rig in the North Sea area with 800 people onboard is essentially doing the same as a humble land rig in east Texas. The same types of equipment and people perform just about the same jobs. Of course, the food is more readily available on the big platforms and they have galleys, television rooms and many other recreational facilities to keep the crew occupied while waiting to go back to work.

|

geologic surface features as streams, roads, and buildings. Base maps are useful for planning exploration, leasing, road building, well placement, and other activities.

geologic surface features as streams, roads, and buildings. Base maps are useful for planning exploration, leasing, road building, well placement, and other activities.

rock. As successive layers of water-saturated sediment accumulate, the deeper layers are compacted by the weight of overlying beds. The individual grains are forced into closer contact and, in some cases, are deformed. Minerals dissolved in the water-commonly, calcite form a solid material that cements the grains together. Much of the water is squeezed out as the sediment is transformed into rock, but some becomes trapped in the pores as connate, or interstitial, water. Rock formed from sediments deposited by water almost always contains interstitial water.

rock. As successive layers of water-saturated sediment accumulate, the deeper layers are compacted by the weight of overlying beds. The individual grains are forced into closer contact and, in some cases, are deformed. Minerals dissolved in the water-commonly, calcite form a solid material that cements the grains together. Much of the water is squeezed out as the sediment is transformed into rock, but some becomes trapped in the pores as connate, or interstitial, water. Rock formed from sediments deposited by water almost always contains interstitial water.

a way that the drilling package is stable and has maximum load bearing capability.

a way that the drilling package is stable and has maximum load bearing capability.

This is quite a reduction in loads to move and makes quite a difference in the time it takes to move the rig. If it takes seven days to move a rig without the moving gear attached it will take approximate sixty hours for the rig move with the moving gear attached.

This is quite a reduction in loads to move and makes quite a difference in the time it takes to move the rig. If it takes seven days to move a rig without the moving gear attached it will take approximate sixty hours for the rig move with the moving gear attached.