Semi-submersible rigs have the advantage of being able to move away from a location very quickly, as opposed to a jack up rig. This is a good thing in arctic areas if an iceberg comes rambling down, at 10 miles per hour, strait on collision course with the rig. Semi-submersible rigs are used for exploration, development and sometimes also for production work in deep waters.

Large semi-submersible rigs can be quite self-contained and can operate for long periods without re-supply. They are more like ships in behavior and require additional equipment to control stability in order to function properly.

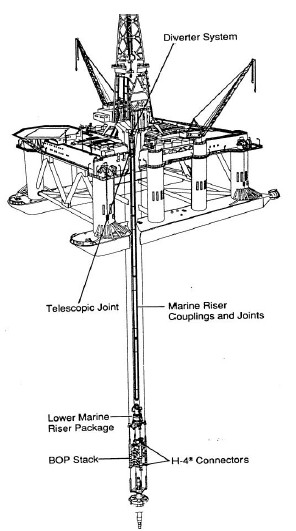

This equipment includes ballast management systems, motion compensators for keeping the drill string on bottom and a riser pipe that isolates the well from the open sea between sea floor and rig. The riser is a set of large pipes which is locked together with seals and bolts in a special way to ensure flexibility and pressure integrity. The riser may have flotation elements attached on the outside to balance the weight of the riser in the water and minimize weight support from rig as this will limit the rigs load capacity.

The Well control equipment (BOP) used on a semi-submersible rig are normally attached to the top of the wellhead at the seafloor. This equipment is remote controlled from the rig through an umbilical or hoses. The main reason for placing the BOP on the sea floor is to prevent high pressure well conditions to enter the riser. As the riser has to be large enough to allow drill string, bit and various casing sizes to pass through, it also has to be strong enough to withstand high well bore pressures. Most risers can hold up to 5000 psi pressure.

There are drilling setups where BOP‘s are located at surface, but then the riser has to have the same pressure rating as the BOP. If the BOP‘s were located at surface, it would be impossible to disconnect at the sea floor as the well would then be open to the environment.tensioner.