Computerized Container Operations

The organization and efficient execution of the loading and unloading operations of a containership is a complex task. Careful coordination and planning of both manpower and equipment is required to obtain the most economical results. Because of its complexity, computer-based data processing and handling technology is of great assistance to the human operator in the efficient execution of this task.

Certain programs were created and installed on the General Electric Mark III Network for use by U.S. Flag operators in the United States. In addition, communication satellites provide U.S. operators access to the same programs and data banks from many maritime jurisdictions including Puerto Rico, Australia, Hong Kong, Japan, and Western Europe. The only user equipment required is an interactive computer terminal, a telephone, and a GE user's number.

Safe and successful deck cargo operations depend on everyone having a good awareness of safety. This includes the deck crew, the personnel on the bridge and the installation. Measures must be taken to minimize the hazards of any dangerous goods; the wearing of the correct PPE is essential in all loading and discharging operations. Where a color coding system is in operation for slings, the vessel should check that all slings are of correct color. The vessel will need to check that each installations cargoes are loaded together. Loads must be placed to make working with them offshore as safe and practical as possible. There must be no need to climbing on cargo units offshore.

During loading the officer on deck should check the tops of all cargo items to make certain that no loose objects, such as spanners, have been left there. The doors and lids of all cargo items must be closed and secured. Open top baskets and containers need to be checked to ensure that the contents are safely stowed and secured. Casing and drill pipes need special attention. They are usually loaded between deck posts and the vessels trash rail. Ideally, all these items should be capped. This is to protect the threads of pipes and stop seawater getting inside casings. Failure to do this can lead to stability problems due to the free surface effect of water inside the casings. are usually loaded between deck posts and the vessels trash rail. Ideally, all these items should be capped. This is to protect the threads of pipes and stop seawater getting inside casings. Failure to do this can lead to stability problems due to the free surface effect of water inside the casings.

Where cargo is in racks, the vessel should check that all items in the rack are secured. Bolts can become loose. Dangerous goods, such as the gas cylinders, helicopter fuel, explosives and radioactive isotopes must be stowed away from accommodation with the correct separation in accordance with the provisions of the IMDG Code or national legislation. Good secure stowage is important for all cargoes as water on the deck can cause them to move. It is especially important for hazardous cargo. Different sectors have different weather working limitations. Once instructions have been received, the weather must be monitored. On a way to the installation, the lashings of the cargo should be checked from time to time, if it is safe to do so, especially if there is a lot of water on deck.

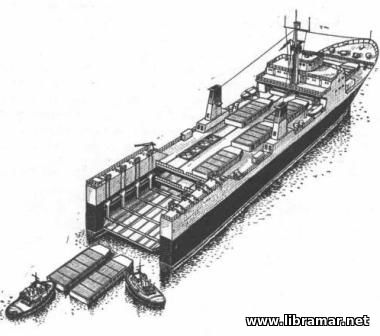

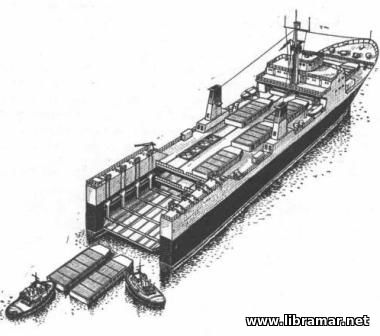

Let us talk a bit more about the barge carrying vessels, playing a very important role in the maritime shipping industry of today, and particularly in transportation of the heavy cargoes. See the previous article for the main discussion. Here we will mainly focus on the SEABEE type of vessel, i.e. the second one.

For the SEABEE type of vessel to empty a full vessel or load a full cargo of barges, giving a theoretical loading or discharge time of 13 hours, it will actually require a theoretical cargo handling total of 64 hours for each round trip, although allowing a 50 percent margin for unforeseen delays, the total cargo handling time is expected to be about four days.

Each barge deck of the SEABEE can accommodate two barge widths, with the upper deck having a capacity for 14 barges while the main and lower decks are each suitable for twelve units, with each hold stowage area measuring 11.1 m (36.54 ft) wide by 5.9 m (19,30 ft) high. As the upper deck is free of obstructions, except in the forward area, it is possible to carry double-width barges or up to ten open-type barges with cargoes of unlimited height, i.e. restricted only by the barge stability limit. It is also possible to carry containers on the top of the upper deck standard type barges.

Hatch covers play a vital role in ensuring that the ship is in fact both seaworthy and cargo-worthy. In a recent study it was found that more than forty percent of all dry bulk cargo insurance claims are directly due to leaking hatch covers and some ships lost at sea under certain circumstances are suspected to have taken water on board in heavy weather due to badly maintained hatch covers. It is very important that the officers and crew are fully aware of the significance of operating the hatch covers correctly and safely.

If costly losses are to be avoided, it is essential that the personnel responsible for operating such equipment must be familiar with its use. Incorrect use and inadequate maintenance will result in a rapid deterioration of hatch cover metal-to-metal contacts, compression bars, rubber seals, particularly cross joint seals, leaving a cargo hold unprotected against the ingress of water. A little water will ruin the cargo; a lot of water can badly affect the stability of the ship which could lead to the loss of lives and the vessel.

We are going to look at the folding type hatch covers and the side rolling hatch covers. The principles of safe  operation and correct maintenance are fortunately common for most systems. Prior to opening, the chains should be inspected to ensure they are of the same length at each side of hatch cover. The wheels should also be inspected and lubricated to ensure that they will run freely and without obstruction. This applies equally to eccentric wheels whose function is to support the hatch covers after lifting from their closed position prior to opening. operation and correct maintenance are fortunately common for most systems. Prior to opening, the chains should be inspected to ensure they are of the same length at each side of hatch cover. The wheels should also be inspected and lubricated to ensure that they will run freely and without obstruction. This applies equally to eccentric wheels whose function is to support the hatch covers after lifting from their closed position prior to opening.

In the case of hydraulically operated folding covers the hydraulic system should also be inspected for leaking and damaged pipes and joints. The hydraulic oil must be kept spotlessly clean at all times. With rack-and-pinion operated systems the gear should be free of dirt and well lubricated. The system must be in good order throughout to achieve both correct opening and closing. In the case of chain or wire-operated systems, the correct tension should be checked.

It is important that the naval architect recognize certain considerations which determine whether the vessel will be efficient in the trade for which intended. Two major elements are the economic factors governing the cargo, and the operating cycle of the ship when engaged in physical movement of the cargo.

Economy of Scale

Surface increases as the square and volume as the cube. Hence the cargo deadweight increases faster than the hull light weight. Further, it requires about the same personnel to move a large ship from point to point as a small one. These considerations of efficiency have promoted the growth of large bulk carriers. As an indicator of the economies to be realized, the Required Freight Rate (RFR), which is the ability to move a ton of cargo without profit, is often used.

However, there are some practical factors which militate against a continued upward growth in the size of vessels. It is necessary to examine the origin and destination of the substance being transported, and as well the route that will be followed between. Vessels of great draft are obviously limited in the ports they can visit and sometimes in the waterways they can traverse.

It was the stimulus of the closing of the Suez Canal in 1956, precluding the use of the relatively shallow Mediterranean Sea as a passage and forcing the much longer distances round the Cape of Good Hope, which provoked the idea of moving great quantities per ship the long distance from the Persian Gulf to northern Europe. At the destination, faced with the limited draft of most northern European ports, it was necessary to transfer into smaller vessels to complete the distribution process.

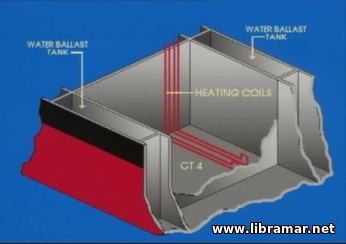

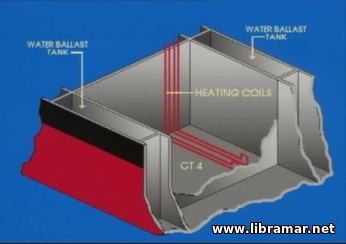

We are now on our way to Europe from West Africa, it is winter and the vessel has received orders to heat the cargo to maintain loading temperature. Our vessel has seven cargo tanks and five permanent ballast tanks, there are two slop tanks directly aft the cargo tank no. 7. All cargo tanks and slop tanks are filled with crude oil. Our vessel has no double bottom. To heat cargo, there are heating coils in the bottom of all cargo tanks. On this ship, there are twelve coils in cargo tank no. 1, fourteen coils in each of the other cargo tanks, and each slop tank has six heating coils. To describe the principle of heating cargo, we will show one coil connected to the simplified heating manifold. Steam is produced by the boiler and is passed to the main heating line on deck via a pressure control valve. From this line, it is passed to the heating manifold serving all individual coils in each cargo tank.

You will get the best heating when the steam condenses to water in the horizontal part of the coil. Here, the steam  cools below its evaporation point and condenses back to water, the heat being absorbed by the oil around the coils. As oil is a poor conductor, heat is mainly distributed by convention currents set up within the tanks. Depending on the pressure in the coils, the temperature of the steam will be between 110 and 160 degrees C. the system shown on the picture has been built to the maximum pressure of 10 kg/cm2. The steam trap allows only water to return to the main return line. There is also a draincock and a filter on every return line. The condensed water is passed back to the boiler through a filter which has an automatic alarm for oil, and then through the hot well tank. This is to ensure that no oil is returned to the boiler. Oil reaching the boiler can create very dangerous situation. cools below its evaporation point and condenses back to water, the heat being absorbed by the oil around the coils. As oil is a poor conductor, heat is mainly distributed by convention currents set up within the tanks. Depending on the pressure in the coils, the temperature of the steam will be between 110 and 160 degrees C. the system shown on the picture has been built to the maximum pressure of 10 kg/cm2. The steam trap allows only water to return to the main return line. There is also a draincock and a filter on every return line. The condensed water is passed back to the boiler through a filter which has an automatic alarm for oil, and then through the hot well tank. This is to ensure that no oil is returned to the boiler. Oil reaching the boiler can create very dangerous situation.

We can be confident that among the first problems seafaring men had to solve before venturing any distance from shore was the transportation of liquid cargo, that is, a supply of fresh water. Across the centuries the retention of an adequate amount of drinkable fresh water at sea has held prime importance. As water craft progressed from canoe and coracle to merchant vessels to men-of-war, the variety of liquids carried increased. Bladders, gourds, jugs, amphorae, casks, and tuns were among the many forms of containers utilized. The ancient craft of cooper had to do with preparation of these containers, and one of the concerns of a ship's carpenter was the staunchness of barrels and kegs aboard.

This transport of liquids in individual, portable quantities and containers continued unchanged until the late 19th century. Several ships were designed after 1863 endeavoring to improve liquid transport, by use of the hull as container. The first oil tanker, Gluckauf, in 1886 with her engine room aft was, in many respects, save for her suit of sails, similar to the tankers of today. She was dedicated exclusively to the carriage of oil, some 2,300 tons, and reportedly served successfully until she ran aground in 1893 on Fire Island. In the course of nearly a century since, oil tankers have grown to vessels carrying over 200 times that quantity.

In the late 1950's the successful experience in the transport of petroleum products in tankers together with the growth of chemical products, many derived from petroleum, brought in the movement of bulk cargos of considerable variety, including the initial experimentation with the transport of cryogenic products such as liquefied natural gas (LNG) and liquefied petroleum gas (LPG). Much of this early activity was conducted in barges plying the Mississippi and Ohio River systems.

In 1961, a hopper barge of minimum reserve buoyancy carrying about 1,000 tons of chlorine in four independent tanks, sank in the vicinity of Natchez, Mississippi, and was lost in the silt of the river bottom. Recovery of the barge and its cargo to eliminate a potential substantial hazard to the general populace cost $4 million. From this incident it was clear that a new system of regulation was necessary.

Loading and discharging bulk cargo is a common procedure for offshore vessels. But it is a very challenging operation. It requires attention to detail and a good awareness of safety issues, whether the cargo is liquid or powder. Before loading the equipment including connections and hoses must be thoroughly checked. Pressure testing may be required. Loading usually takes place at a shore base organized by the charterer. The charterer will determine what quantities of which materials will need to be loaded.

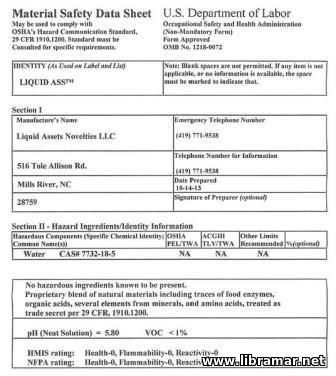

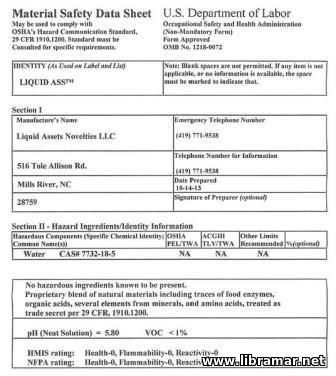

It is essential to make a loading plan with the shore-based staff. This will detail the piping and valves that must be used, the quantities to be loaded, and the expected timing of the procedure. The cargo hazards must be checked and measures taken to minimize the risks of spillage and personnel injury. The correct PPE must be worn. The MSDS – Material Safety Data Sheet - will indicate what is required. Liquid cargoes vary in their hazards - some, like potable water, present little hazard; others, like fuel oil or methanol, are hazardous. If the cargo is hazardous, safety and spill response equipment must be put in place ready for use.

The connection of the shore hose requires attention to the proper connecting procedures. Once the loading is underway, the flow must be monitored. There must be continual checking that no leaks develop. The pressurized air used to load dry bulk products is a hazard itself. Safety glasses should be worn for any job that could involve loose chippings. The loading hoses must be secured to prevent their moving and becoming a hazard. Where the venting hose is placed in the water, it must be properly weighted and placed away from the jetty.

All hoses including the venting hose must be monitored during loading. Slower rates of cargo transfer should be used at the start and near completion. Once loading is complete, the pipework and hoses must be purged, depressurized and then disconnected. The air pressure in the hose is released by a vent valve. But these valves can become blocked and must be checked and cleaned if necessary before venting. On completion of loading liquid bulk cargo, the hoses will need to be dried before disconnection.

Before the vessel begins operations offshore, there must be a discharge plan agreed with the installation. Everyone on deck needs to know what they have to do and how long it is expected to take. Checklists may need to be completed and signed by the vessel and the installation. The type of connection to the installation hose must be known and understood by the deck crew. The installation will pass down the hose once they are ready. The vessel’s pumps or air compressors will be needed. Before the vessel begins operations offshore, there must be a discharge plan agreed with the installation. Everyone on deck needs to know what they have to do and how long it is expected to take. Checklists may need to be completed and signed by the vessel and the installation. The type of connection to the installation hose must be known and understood by the deck crew. The installation will pass down the hose once they are ready. The vessel’s pumps or air compressors will be needed.

The hose shall be long enough to allow for the vessel’s movement. Ideally, it would have floatation colors. The hose should be secured so that it can be seen from the bridge and so that it will not interfere with the propellers or thrusters. At night, the hose will need to be lit. Before starting either liquid or dry bulk cargo discharge, the vessel’s working pressure and emergency stopping procedures must be discussed and agreed with the installation. The bridge must be adequately manned to cover both maneuvering the vessel and cargo operations taking place. Personnel on deck must always aware of what is going on around them and any potential hazards.

Direct physical contact with any bulk cargo other than water must be avoided. If any cargo gets on exposed skin, it must be washed off immediately. Once the transfer is underway, the main task is monitoring the flow. If there is a problem, it is better to cause a delay by stopping the operation rather than risking pollution or injury. At all times, there must be a good communication with the installation.

During dry bulk cargo operations, the installation will monitor their vent. The bridge should do so too as this can give warning of  cargo blockages. With powder cargo, this is quite likely to occur. On completion of dry bulk cargo, the hoses and pipework will need to be purged, depressurized and disconnected. The air pressure must be vented from the hose. Deck crew should check that the hose is less rigid before they disconnect it. cargo blockages. With powder cargo, this is quite likely to occur. On completion of dry bulk cargo, the hoses and pipework will need to be purged, depressurized and disconnected. The air pressure must be vented from the hose. Deck crew should check that the hose is less rigid before they disconnect it.

It is possible that the installation will need to back load bulk liquids, often contaminated liquid muds so the vessel shall be aware of the chemical hazards associated with these muds. There must be a proper plan, agreed upon pressures and emergency stopping procedures. On completion of all liquid cargo operations, the hose will need to be drained back to the vessel to ensure there is no spillage. If hoses, pipework, or tanks need cleaning, established procedures shall be followed in line with MARPOL requirements.

|

are usually loaded between deck posts and the vessels trash rail. Ideally, all these items should be capped. This is to protect the threads of pipes and stop seawater getting inside casings. Failure to do this can lead to stability problems due to the free surface effect of water inside the casings.

are usually loaded between deck posts and the vessels trash rail. Ideally, all these items should be capped. This is to protect the threads of pipes and stop seawater getting inside casings. Failure to do this can lead to stability problems due to the free surface effect of water inside the casings.

operation and correct maintenance are fortunately common for most systems. Prior to opening, the chains should be inspected to ensure they are of the same length at each side of hatch cover. The wheels should also be inspected and lubricated to ensure that they will run freely and without obstruction. This applies equally to eccentric wheels whose function is to support the hatch covers after lifting from their closed position prior to opening.

operation and correct maintenance are fortunately common for most systems. Prior to opening, the chains should be inspected to ensure they are of the same length at each side of hatch cover. The wheels should also be inspected and lubricated to ensure that they will run freely and without obstruction. This applies equally to eccentric wheels whose function is to support the hatch covers after lifting from their closed position prior to opening.

cools below its evaporation point and condenses back to water, the heat being absorbed by the oil around the coils. As oil is a poor conductor, heat is mainly distributed by convention currents set up within the tanks. Depending on the pressure in the coils, the temperature of the steam will be between 110 and 160 degrees C. the system shown on the picture has been built to the maximum pressure of 10 kg/cm2. The steam trap allows only water to return to the main return line. There is also a draincock and a filter on every return line. The condensed water is passed back to the boiler through a filter which has an automatic alarm for oil, and then through the hot well tank. This is to ensure that no oil is returned to the boiler. Oil reaching the boiler can create very dangerous situation.

cools below its evaporation point and condenses back to water, the heat being absorbed by the oil around the coils. As oil is a poor conductor, heat is mainly distributed by convention currents set up within the tanks. Depending on the pressure in the coils, the temperature of the steam will be between 110 and 160 degrees C. the system shown on the picture has been built to the maximum pressure of 10 kg/cm2. The steam trap allows only water to return to the main return line. There is also a draincock and a filter on every return line. The condensed water is passed back to the boiler through a filter which has an automatic alarm for oil, and then through the hot well tank. This is to ensure that no oil is returned to the boiler. Oil reaching the boiler can create very dangerous situation.

Before the vessel begins operations offshore, there must be a discharge plan agreed with the installation. Everyone on deck needs to know what they have to do and how long it is expected to take. Checklists may need to be completed and signed by the vessel and the installation. The type of connection to the installation hose must be known and understood by the deck crew. The installation will pass down the hose once they are ready. The vessel’s pumps or air compressors will be needed.

Before the vessel begins operations offshore, there must be a discharge plan agreed with the installation. Everyone on deck needs to know what they have to do and how long it is expected to take. Checklists may need to be completed and signed by the vessel and the installation. The type of connection to the installation hose must be known and understood by the deck crew. The installation will pass down the hose once they are ready. The vessel’s pumps or air compressors will be needed. cargo blockages. With powder cargo, this is quite likely to occur. On completion of dry bulk cargo, the hoses and pipework will need to be purged, depressurized and disconnected. The air pressure must be vented from the hose. Deck crew should check that the hose is less rigid before they disconnect it.

cargo blockages. With powder cargo, this is quite likely to occur. On completion of dry bulk cargo, the hoses and pipework will need to be purged, depressurized and disconnected. The air pressure must be vented from the hose. Deck crew should check that the hose is less rigid before they disconnect it.