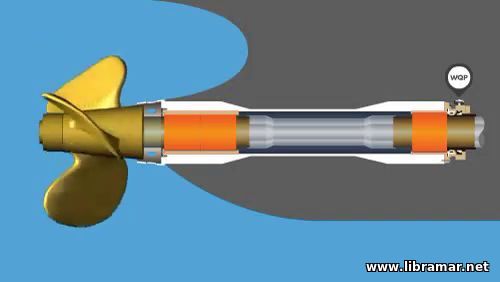

Here is a very short video animation briefly demonstrating the functioning of the sea water lubricated propeller shaft bearings by Thordon. Subject COMPAC bearings feature long and very predictable wear life and fifteen years of guaranteed service.

They have already proven effective in many commercial vessels - more than six hundred vessels today have Thordon sea-water lubricated bearings installed within their propeller shaft arrangements.

The vessel crew will not have to care about the leakage of oil from the bearings in case they get damaged since there is no oil used in them, and that is why there is no risk of environmental pollution.

They are also featuring much lower operating costs and offer many other advantages that will be appreciated by the ship owners...