Ballast Water Management Methods

Let us talk about various techniques used for treating ballast water. Limiting the amount of ballast taken is the first step in an effective ballast management plan. Practices that minimize the intake of port and coastal sediments can also be effective in reducing aquatic introductions. Ballasting should be avoided in very shallow waters, in stagnant areas, in the vicinity of sewage outflows and dredging operations, in areas where known pathogens are present etc. Whenever practical, the loading of ballast water should be delayed until the ship is in open ocean waters.

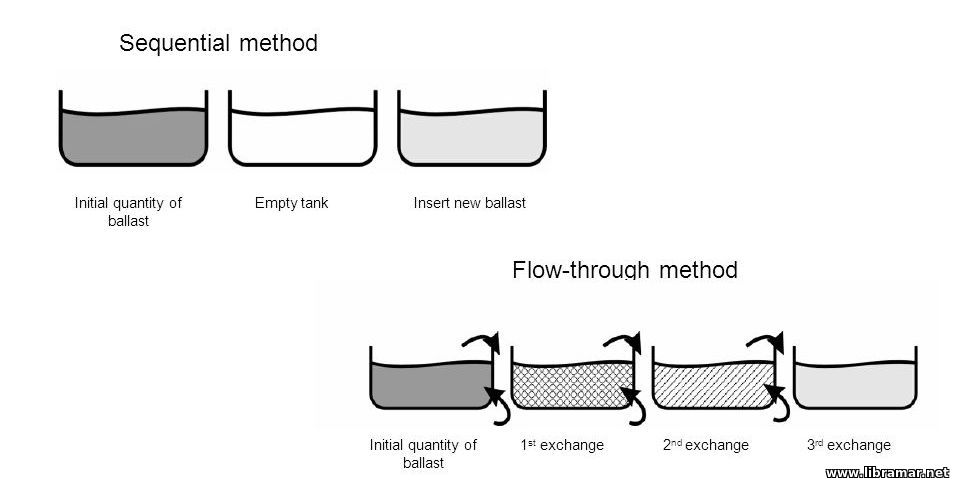

Ballast water exchange is currently considered the single most practical method for ballast water management. Ballast water exchange can be accomplished by either the sequential empty-refill method or by flow through, also referred to as the overflow method. It has been reported that these methods are about 95% effective in eliminating aquatic organisms. Ballast water exchange operations should be performed in deep water away from coastal shelves and estuary influences.

Sequential Method

Sequential method is where all ballast tanks are completely emptied and refilled at sea step by step, one or more tanks at a time, until all ballast has been replaced. The sequential method requires considerable planning to ensure that the ship will remain within accepted criteria. The primary considerations is assessing sequential exchange scenarios focus on vessel's stability, hull girder strength, propeller immersion, bridge visibility, list angle and, in addition, the effect of slamming, swashing, and damage stability.

Flow Through Method

The flow through method, whereby tanks are overfilled by pumping in additional water, has the advantage that it can be used in weather conditions which would be marginal for use of the sequential method since there is little change to the condition of the ship. Researchers established that it is necessary to pump in three times the volume of the tank to achieve a 95% change of water. Pumping in only once a volume of the tank produces a 64% exchange. Twice the volume produces 86% exchange while four times of volume produces a 98% water exchange.

All ballast exchange must be carefully planned and the following aspects should be taken into consideration:

- - Avoiding of an over- and under-pressurization of ballast tanks

- - Surface effects on stability and slashing loads in tanks that may be slack at any one time

- - Admissible weather conditions

- - Weather routeing in areas seasonably affected by cyclones, typhoons, hurricanes or heavy icing conditions

- - Maintenance of adequate intact stability in accordance with an approved Trim and Stability Booklet

- - Permissible sea-going stress limits of shear forces and bending moments in accordance with an approved Loading Manual

- - Torsional forces where relevant

- - Minimum/maximum forward and aft drafts

- - Documented records of ballasting and/or de-ballasting

- - Contingency procedures for situations which may affect the ballast water exchange at sea including deteriorating weather conditions, pump failure, loss of power, etc.

- - Time to complete the ballast water exchange on appropriate sequence thereof taking into account that the ballast water may represent 50% of a total cargo capacity for some ships

- - Monitoring and controlling the amount of ballast water

If permissible by vessel's draft, one alternative is to retain all ballast on board. If the vessel must shift the ballast water while in ports to maintain list or trim, this should as far as practical be done without discharging any ballast. If ballast exchange has not been possible, some ports have the facilities to receive ballast water ashore.

When ballasting a vessel, there will always be particles and mud entering the ballast tanks together with the water. These particles and mud will form sediment. This sediment has to be removed at regular intervals. Consult the Ballast Water Management Plan on board your vessel or ask you ballast water management officer about the interval. The sediment can contain more harmful species than the water. Only dispose of sediment in mid-ocean or to a reception facility ashore.

In case of an emergency, a local authority must be contacted before any ballast water is pumped out in the sea. The possibility is in an emergency can be:

- - A decision not to treat

- - Physical treatment, for example heat or UV-radiation

- - Chemical treatment, chemical sanitization

The Convention promotes new techniques for ballast water management. The requirements for new techniques are:

- - It must be safe

- - It must be environmentally acceptable

- - It must be cost-effective

- - It must work

There are several ballast water management techniques under development:

- - Mechanical treatment methods, such as filtration and separation

- - Physical treatment methods, such as sterilization by ozone, ultraviolet light, electric currents, and heat treatment

- - Chemical treatment methods, such as adding biocides to ballast water to kill organisms

- - Various combinations of the above

Ballast water can be filtered before it enters the tanks or while it is being discharged. The advantage of filtering water is pumped into the tanks is that organisms that are filtered out can be retained in native habitat. If ballast water is filtered while being discharged, proper disposal of organisms is required to eliminate accidental introductions. One of the main drawbacks to filtration is that it requires specialized equipment which may be expensive to purchase and install. The cost of filtration increases as smaller particles and organisms are removed from ballast water since the sizes of filters used to treat ballast water are not likely to remove microorganisms and there is a need for another method to remove them. New techniques are developing ways to increase the flow rates through filters and prevent organisms from clogging filters making this method of treatment more useful.

Heating ballast water to temperatures between 35 and 40 degrees Celsius and maintaining that temperature for a long enough period of time is effective in killing larger organisms such as fish, but not as effective in killing microorganisms. Ballast water is heated by using the engine cooling system either by using ballast water to cool the engine or by flushing ballast tanks with the heated water that was used as coolant. This is a very efficient method because coolant water is necessary and would most likely be discharged into the ocean if not used to treat ballast water. Another benefit of this method is that there are no resulting by-pass chemical products.

The "Read Later" function allows you to add material to this block with just one click. Just click on the icon and read the articles that interest you at any convenient time.