Cargo Heating on Tanker Ships

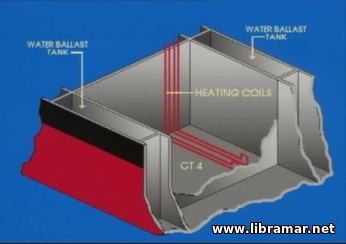

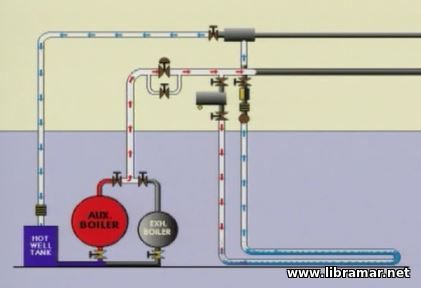

We are now on our way to Europe from West Africa, it is winter and the vessel has received orders to heat the cargo to maintain loading temperature. Our vessel has seven cargo tanks and five permanent ballast tanks, there are two slop tanks directly aft the cargo tank no. 7. All cargo tanks and slop tanks are filled with crude oil. Our vessel has no double bottom. To heat cargo, there are heating coils in the bottom of all cargo tanks. On this ship, there are twelve coils in cargo tank no. 1, fourteen coils in each of the other cargo tanks, and each slop tank has six heating coils. To describe the principle of heating cargo, we will show one coil connected to the simplified heating manifold. Steam is produced by the boiler and is passed to the main heating line on deck via a pressure control valve. From this line, it is passed to the heating manifold serving all individual coils in each cargo tank.

You will get the best heating when the steam condenses to water in the horizontal part of the coil. Here, the steam  cools below its evaporation point and condenses back to water, the heat being absorbed by the oil around the coils. As oil is a poor conductor, heat is mainly distributed by convention currents set up within the tanks. Depending on the pressure in the coils, the temperature of the steam will be between 110 and 160 degrees C. the system shown on the picture has been built to the maximum pressure of 10 kg/cm2. The steam trap allows only water to return to the main return line. There is also a draincock and a filter on every return line. The condensed water is passed back to the boiler through a filter which has an automatic alarm for oil, and then through the hot well tank. This is to ensure that no oil is returned to the boiler. Oil reaching the boiler can create very dangerous situation.

cools below its evaporation point and condenses back to water, the heat being absorbed by the oil around the coils. As oil is a poor conductor, heat is mainly distributed by convention currents set up within the tanks. Depending on the pressure in the coils, the temperature of the steam will be between 110 and 160 degrees C. the system shown on the picture has been built to the maximum pressure of 10 kg/cm2. The steam trap allows only water to return to the main return line. There is also a draincock and a filter on every return line. The condensed water is passed back to the boiler through a filter which has an automatic alarm for oil, and then through the hot well tank. This is to ensure that no oil is returned to the boiler. Oil reaching the boiler can create very dangerous situation.

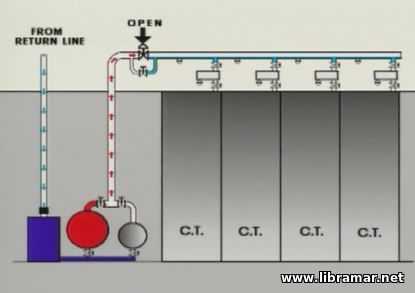

The temperatures in our tanks are falling and it is time to activate coils. Starting up heating will probably take you most of your working day. It is important to take your time to warm the main steam line properly. If this long line is fed too much steam, it may break and you cannot heat the cargo until the line is repaired. So, it is good idea to first use the bypass valve when warming the main steam line. To proceed, first you should drain the line of water through the  draincocks. Leave them open. Now, you may ask the engine room to warm the steam line. It can take several hours to heat the line so be patient to not rush. Close the draincocks one by one when steam is coming through them.

draincocks. Leave them open. Now, you may ask the engine room to warm the steam line. It can take several hours to heat the line so be patient to not rush. Close the draincocks one by one when steam is coming through them.

The next step – all coils must be checked for leaks and traces of oil. Water must be circulated through every coil and pass to deck via the draincocks. The entire length of the coils must be flushed through – this will take some time. Consider the volume of the coil and measure the amount of water passing through the draincock per minute. It is not enough to flush a coil for 10-15 minutes. You can probably flush several coils at the same time but supervision, checking for traces of oil, is difficult, especially at night.

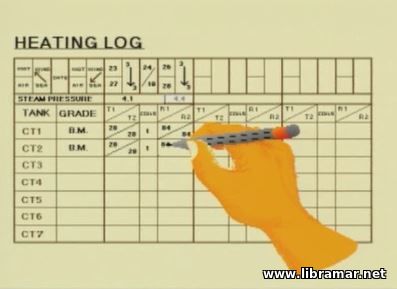

When the heating is started, cargo temperature should be taken in the morning and evening. All important data is recorded in the heating log. Date, morning temperatures of sea water and air, relative wind direction and the state of the sea, pressure and time of changes along with steam pressure line are noted. Also, note the number of activated coils in the tank. There is also an entry for the fuel consumption. Remember, the ship’s cargo tanks are insulated from the passing sea water on the sides by the ballast tanks, but the bottom is cooled by the sea and the deck is cooled by the wind and sea spray.

the wind and sea spray.

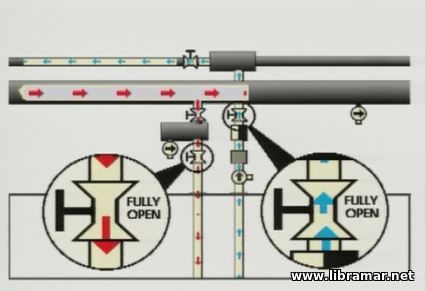

Now, the temperature is falling and it is time to activate the coils. The inlet valve is fully open and the return valve is partly open at first. After a while, when water is flowing through the return drain, the return valve is fully opened and the return drain is closed. Observe that the inlet valve should be fully open. The normal position of the valves is either fully open or closed. You should regulate the heating by the number of coils activated and the main steam pressure. If you need to manipulate the flow, always use the return valve. To observe the system’s response to your different actions, measure the temperature of the return water.

You should always try to keep an intended temperature using as few coils as possible and with lowest possible steam pressure. If the temperature is generally falling in the tanks, activate more heating coils or increase the steam pressure. If the temperature is still falling with all coils active, increase further the steam pressure. If the temperature generally tends to rise in the tanks, close coils or reduce the steam pressure. If the temperature in a separate tank differs from the rest, open or close heating coils.

The forward tanks are always harder to heat than he aft tanks. Towards the end of the trip, with all coils activated and heating at maximum capacity, you may have to close coils in the aft cargo tanks to direct more steam forward. Remember, heating cargo is easier is sheltered waters.

The forward tanks are always harder to heat than he aft tanks. Towards the end of the trip, with all coils activated and heating at maximum capacity, you may have to close coils in the aft cargo tanks to direct more steam forward. Remember, heating cargo is easier is sheltered waters.

During discharge, the heating should be stopped before the coils are exposed. Close the inlet valve first. Do not close the inlet and the outlet valves at the same time. If this is done, an under-pressure will develop in the coil when steam turns back to water. Oil may one way or another sneak into the coil, giving a false indication of a leaking coil. Keep the return draincock open in order to avoid such under-pressure.

In a crude oil carrier, there is one simple way to maintain and control the vessel’s heating system. Keep the heating coils completely filled with fresh water when they are not in use. However, there is one exception – if there is a risk of freezing temperatures, empty the whole system of water by blowing through with air. Note that fresh water expands when the temperature begins to fall below 4 degrees C and with subsequent falling of the temperature it turns to ice. If ice blocks the expanding water, a coil will break.

Turning back to normal maintenance, always check for leaky and faulty coils. Take every opportunity to test them. This can be done by pressurizing the main steam line with air. Open the drains and then the inlet valves one by one. If water comes flowing relatively quickly through the return drain, this indicates a healthy coil. If there is no water flow or  less than expected or even boil flows, you probably have a leaking coil. If there is a leak in a fully loaded tank, and the return draincock is open water, propelled by the inert gas pressure, will start to flow to deck. If there is a leak on a coil in an empty tank, the water will leak into the tank. An empty coil means trouble.

less than expected or even boil flows, you probably have a leaking coil. If there is a leak in a fully loaded tank, and the return draincock is open water, propelled by the inert gas pressure, will start to flow to deck. If there is a leak on a coil in an empty tank, the water will leak into the tank. An empty coil means trouble.

Keep in mind that the coils are the weak link in this system. Check them every trip or at least once a month. Checking the coils with air is fast and easy. Every six months the heating coils should be properly tested with water pressure. Do not just ignore the heating system during periods when cargoes are not heated. It is a vulnerable system and needs your attention to function on the day you need it.

The "Read Later" function allows you to add material to this block with just one click. Just click on the icon and read the articles that interest you at any convenient time.