Functions of the Drill Collars

Let us shed some light on the important functions of the string of drill collars.

Weight on Bit

As discussed earlier, drill collars provide weight on the bit in order to make the bit gouge into the earth and make hole. The amount of weight required depends on several factors. The well planner considers the kind of formations being drilled, the diameter of the hole, the kind of bit being used to drill, the buoyant effect of the drilling fluid, the tendency of the hole to deviate from a true vertical path, and other variables. The correct amount of weight on the bit helps make for efficient drilling of the hole. The weight of each drill collar depends on the OD and the ID, or bore, of the pipe. The weight or force needed on the bit will significantly differ depending on the diameter of the hole.

The buoyant effect of the drilling fluid in the hole must be taken into consideration when determining WOB. Just as a boat floats  on water, the drill stem floats in drilling fluid, thereby reducing the amount of weight on the bit. The denser the drilling fluid, the greater the buoyant effect, so more drill collars are needed to provide the same weight on the bit. Drilling crews often use additional collars to offset this buoyancy. To account for the buoyant effect of the drilling fluid, the operator takes the required WOB and divides it by the buoyancy factor of the mud to arrive at the air weight of the drill collars.

on water, the drill stem floats in drilling fluid, thereby reducing the amount of weight on the bit. The denser the drilling fluid, the greater the buoyant effect, so more drill collars are needed to provide the same weight on the bit. Drilling crews often use additional collars to offset this buoyancy. To account for the buoyant effect of the drilling fluid, the operator takes the required WOB and divides it by the buoyancy factor of the mud to arrive at the air weight of the drill collars.

The amount of deviation in the wellbore must also be taken into consideration when determining WOB. The more the hole deviates from vertical, the greater is the reduction in effective WOB. So, depending on how much the hole deviates from vertical, the well planner must increase the number of drill collars to provide the required WOB.

Holding the Drill String Straight

In addition to putting weight on the bit to make hole efficiently, drilling crews must also use the weight of the collars to keep the drill string above the collars from bending or buckling. If the drill string is kept in tension, it will not bend or buckle. The drill string is kept in tension by two opposing forces – the weight of the drill collars pulling it from below and the drawworks and drilling line pulling it from the surface.

Under normal condition, the drill pipe string wears more rapidly near the center of each joint. Bending or buckling increases the metal fatigue in the center of the joint – that is, bending increases the stress factors in the pipe’s weakest area. Bending also forces the drill string to rub against the wall of the hole, which abrades the sides of the pipe.

Sometimes the driller uses extra weight on the collars to make sure that the drill string stays straight. When using additional weights to hold the drill string straight, the driller usually uses drill collars having a buoyed weight 10% to 30% greater than the amount needed to just to make hole. Providing this extra weight will help keep the string relatively straight as it is rotated.

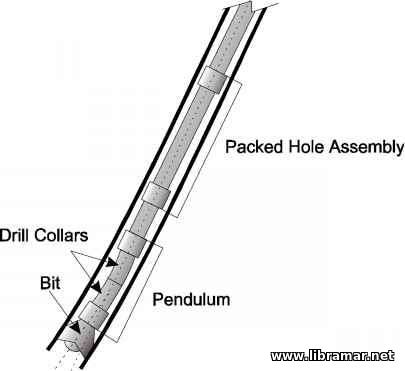

Providing a Pendulum Effect

Drill collar weight also provides a pendulum effect to cause the bit a drill a more nearly vertical hole. In straight-hole drilling, the most efficient drilling is that which produces a nearly vertical path to the target. Any deviation from vertical tends to increase the cost of the well. Of course, no hole is absolutely vertical from the surface to completion. Different causes force the hole to deviate from  vertical. The job of the drilling crew is to keep the wellbore as vertical as possible.

vertical. The job of the drilling crew is to keep the wellbore as vertical as possible.

As stated previously, one phenomenon that assists the driller in straight-hole drilling is the pendulum effect. The pendulum effect is the tendency of the drill stem to hang in a vertical position because of the force of gravity pulling on the drill collars. The heavier the pendulum, the stronger is its tendency to remain vertical and the greater is the force needed to cause the drill stem to deviate from vertical. If the drill stem deviates from a true vertical path, the force of gravity tends to pull it back toward vertical. The bit and drill collars tend to drill on the low side of the hole as they seek a more nearly vertical path.

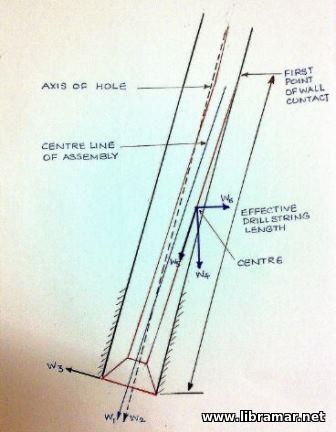

The length of the pendulum is that section of the drill collar string between the bit and the lowest-point tangent to the side of the hole. The lowest-point tangent to the side of the hole is the point at which the drill collars first touch the sides of the hole or at which the first stabilizer touches the sides of the hole. The drilling crew tries to keep this point as high as practical so that the pendulum will be as long as possible. The longer the pendulum, the greater is the tendency for the drill stem to seek a vertical position. There is a limit, however, on the spacing between the bit and the first stabilizer. If the distance is too great, the drill collars may buckle. Tables are available to assist in selecting the appropriate spacing in relation to hole size, drill collar OD and ID, and the angle of the hole.

The weight, the length, and the stiffness of the pendulum are important in straight-hole drilling. A stiff drill collar assembly has a higher point of tangency than a limber one. To achieve both weight and stiffness, crew use large, heavy collars. Undersized and relatively limber drill collars, with a large clearance between the OD of the collar and the wall of the hole, make it harder to keep the hole vertical. Relatively limber drill collar strings tend to bend or flex near the bit; this bending shortens the pendulum considerably  and increases the deviation from vertical.

and increases the deviation from vertical.

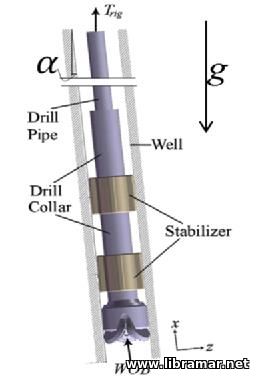

Stabilizing the Bit

Drilling crews use large, heavy, round drill collars with stabilizers to help stabilize the bit when drilling. They use these collars and stabilizers to create what is called a packed bottomhole assembly, or BHA. This term refers to the fact that round drill collars with stabilizers in the lower part of the drill collar assembly are almost the same OD as the bit. In addition, the stabilizers are no more than 1/8 inch smaller in diameter than the hole. In a packed BHA composed of a bit and round drill collars with three or more stabilizers above it, the crew places the first stabilizer immediately above the bit, followed by a short, large-diameter drill collar and a second stabilizer. The third stabilizer is located farther up in the drill collar string.

The use of a packed bottomhole assembly is sometimes referred to as a gun-barrel approach because when the crew uses this assembly, the bit tends to drill straight ahead in spite of forces trying to prevent it from doing so. In other words, the assembly assures that the new wellbore is being drilled in line with the hole that has already been drilled; it is as straight as the barrel of a gun. Using a packed BHA, or the gun-barrel approach, keeps the bit from wobbling, or walking, on the bottom of the hole. This approach also keeps the pressure on the cutting structure of the bit uniform, thereby forcing the bit to cut evenly through the formation. A bit that is not connected to a packed bottomhole assembly may drill an oversize hole, produce unusual bit wear, and slow the rate of penetration. In general, bits drill faster and last longer when well stabilized.

The "Read Later" function allows you to add material to this block with just one click. Just click on the icon and read the articles that interest you at any convenient time.