Operation and Maintenance of Shipboard Hatch Covers

Hatch covers play a vital role in ensuring that the ship is in fact both seaworthy and cargo-worthy. In a recent study it was found that more than forty percent of all dry bulk cargo insurance claims are directly due to leaking hatch covers and some ships lost at sea under certain circumstances are suspected to have taken water on board in heavy weather due to badly maintained hatch covers. It is very important that the officers and crew are fully aware of the significance of operating the hatch covers correctly and safely.

If costly losses are to be avoided, it is essential that the personnel responsible for operating such equipment must be familiar with its use. Incorrect use and inadequate maintenance will result in a rapid deterioration of hatch cover metal-to-metal contacts, compression bars, rubber seals, particularly cross joint seals, leaving a cargo hold unprotected against the ingress of water. A little water will ruin the cargo; a lot of water can badly affect the stability of the ship which could lead to the loss of lives and the vessel.

We are going to look at the folding type hatch covers and the side rolling hatch covers. The principles of safe  operation and correct maintenance are fortunately common for most systems. Prior to opening, the chains should be inspected to ensure they are of the same length at each side of hatch cover. The wheels should also be inspected and lubricated to ensure that they will run freely and without obstruction. This applies equally to eccentric wheels whose function is to support the hatch covers after lifting from their closed position prior to opening.

operation and correct maintenance are fortunately common for most systems. Prior to opening, the chains should be inspected to ensure they are of the same length at each side of hatch cover. The wheels should also be inspected and lubricated to ensure that they will run freely and without obstruction. This applies equally to eccentric wheels whose function is to support the hatch covers after lifting from their closed position prior to opening.

In the case of hydraulically operated folding covers the hydraulic system should also be inspected for leaking and damaged pipes and joints. The hydraulic oil must be kept spotlessly clean at all times. With rack-and-pinion operated systems the gear should be free of dirt and well lubricated. The system must be in good order throughout to achieve both correct opening and closing. In the case of chain or wire-operated systems, the correct tension should be checked.

Opening a hatch cover, sometimes very large and heavy one, means removing it from its safest condition. It must therefore be done with great care. If the hatch cover has carried substantial weight, such as containers, it should be inspected prior to opening for any possible damage. If any deformation or other signs of damage are observed, this should be reported to the chief engineer before the opening procedure commences.

If all seems well, the opening process must involve the following steps in the correct order:

- Check the power unit and switch on;

- Remove the hatch cover securing devices;

- Check the safety devices to make sure that they are present and in working order;

- Clear the area concerned and warn all interested parties that the hatch covers are about to be opened;

- Make sure that this can be done safely;

- Operate wheel lifting devices to lift the covers ready for moving;

- Operate the power system and open the hatch covers into the stowed or opened position;

- Observe hatch covers during opening for any uneven movement or irregular speed or abnormal vibration;

- As soon as the hatch covers are stowed, or in the case of the side rolling type, reached their open position, attach the locking devices and ensure that they hold the hatch covers securely in place;

- Now the power unit can be safely shut down.

A ship aims to be in port for as shorter time as possible. Cargo operations are completed as quickly as circumstances permit, yet the only time when the routine inspection of hatch covers, cross joints, seals and rails can be carried out is when the hatch covers are open. A scheduled inspection program should be therefore carried out each time the covers are opened. Unfortunately, due to pressure of time and schedules, too often hatch cover operation is left unsupervised by officers and is rushed by crew members. Little attention is paid to the need for inspection and maintenance due particularly smaller and smaller crew numbers being on board. Inevitably, this may cause major losses or cargo, injuries, mechanical damage, and even loss of the ship.

A ship aims to be in port for as shorter time as possible. Cargo operations are completed as quickly as circumstances permit, yet the only time when the routine inspection of hatch covers, cross joints, seals and rails can be carried out is when the hatch covers are open. A scheduled inspection program should be therefore carried out each time the covers are opened. Unfortunately, due to pressure of time and schedules, too often hatch cover operation is left unsupervised by officers and is rushed by crew members. Little attention is paid to the need for inspection and maintenance due particularly smaller and smaller crew numbers being on board. Inevitably, this may cause major losses or cargo, injuries, mechanical damage, and even loss of the ship.

Hatch cover inspection can be carried out at various levels, involving different people and different objectives.

The inspections carried out by the officers and crew of the ship as part of their scheduled housekeeping operation is aimed to identifying any developing problems arising from normal wear with special attention given to metal-to-metal contacts, compression bars, rubber seals and securing devices. The drainage channels and valves should also be inspected. Serious wear and corrosion should have immediate attention.

The inspection by a company engineering superintendent is carried out at intervals to establish the general condition of hatch covers before dry dock to assess the work to be done.

Inspection by manufacturers or specialist firms is carried out when requested or scheduled to provide surveys and  solutions to major problems.

solutions to major problems.

Once the inspection has been completed, general housekeeping operation should take place according to the company’s schedules. This is the first level of normal operational maintenance.

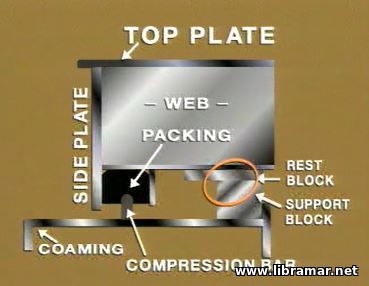

Chains or wires should be checked for equal length at both sides of the cover to ensure equal pool. If the lengths are uneven, this should be remedied. Compression bars and rubber seals should also be maintained according to the planned schedule and, if found worn or corroded, they should be cleaned and rebuilt. On finding worn or compressed rubber seals, the usual inclination is to replace them. However, consideration must also be given to the main cause of their poor condition. Since seal deterioration is often a sign of the steelwork problems, seal replacement may only be a short term solution. The problem in fact usually lies with the metal-to-metal contacts which are worn or corroded.

The manufacturers design the metal-to-metal contact to precise height in order to provide the correct pressure on the rubber seals. Once the surfaces become worn or corroded, the hatch cover sits lower on the compression bars, increasing this pressure. Over-compressed rubber seals lose their elasticity well ahead of time, losing their sealing efficiency. Simply replacing the rubber seals only serves to ruin them ahead of time and is a waste of money.

The real solution to worn or over-compressed rubber seals is first to rebuild the metal-to-metal contact surfaces to their original dimensions with assistance of the manufacturer and then to fit new rubber seals. They will then work as designed by the manufacturer. This should be carried out at the first convenient moment.

The rack-and-pinion system powered system must be cleaned and lubricated. If it is a chain-operated system, the chains must be correctly adjusted and well lubricated. Hydraulic systems must be checked for any leakage or hose damage and must be kept clean. Hinge pins must also be checked. The hydraulic fluid should be checked and samples sent away for analysis periodically.

The rack-and-pinion system powered system must be cleaned and lubricated. If it is a chain-operated system, the chains must be correctly adjusted and well lubricated. Hydraulic systems must be checked for any leakage or hose damage and must be kept clean. Hinge pins must also be checked. The hydraulic fluid should be checked and samples sent away for analysis periodically.

The cargo unloading operation has been completed and orders go out to shut the hatch covers. The closing procedure should always start with an inspection to check if there was any damage caused by the cargo handling operation which would prevent the proper operation of the hatch covers, and to see that the coaming tops are free from dirt and obstacles.

With single pull wire operated systems the retaining wire is attached at this stage. If your system is hydraulically operated, this is a time to turn the hydraulic power on. The safety catchers can now be removed to allow the hatch cover to move freely. The power unit is operated to close the hatch covers. The operation must be observed carefully for any signs of unexpected vibration or uneven closing speed as these symptoms can give an indication of presence of heavy wear or damage.

The wheels are then lowered by the appropriate method. The securing devices are attached to hold the covers in the closed position. The power units can now be shut down. If the ship is cargo-free, a water hose test can be carried out. Water is directed into the hatch covers in the compression bar and cross sealing areas from about 1 meter distance. Drain channels should be blocked to ensure that the water reaches the level of the seals.

A more modern and increasingly used method of testing hatch cover efficiency is the ultra-sound method. Whichever method is used, the tests should be carried out regularly and any adverse trends developing should be  discussed with the chief engineer. This method can be carried out when the vessel is loaded.

discussed with the chief engineer. This method can be carried out when the vessel is loaded.

When the hatch covers do not lie flat on the coaming rails or do not align in height, this is the indication of deformation, damage or excessive wear of the metal-to-metal contacts. In this case the rubber seals may also be suspected and should be investigated. If there is some damage to the covers which cannot be repaired until the ship reaches the next destination, the use of sealing tape may provide a temporary answer, but remember that the hatch covers do not perform correctly and the use of sealing tape is only a first-aid measure. Prolonged use will accelerate corrosion in that area.

The "Read Later" function allows you to add material to this block with just one click. Just click on the icon and read the articles that interest you at any convenient time.