We have already covered the standard drill collar design in the previous article. Now, let us have a look in two special designs commonly used in rotary drilling, in addition to the standard one.

Spiral Collars

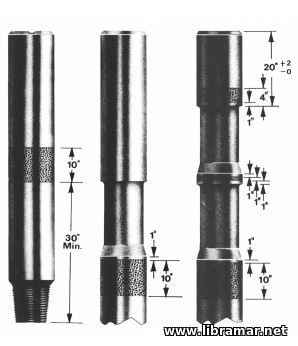

Although most collars are round, engineers design some collars to counteract specific problems that can develop while drilling. For instance, some collars may have spiral grooves machined into the outside surface. Drillers sometimes use spiral drill collars in holes in which the clearance between the drill collar and the wall of the hole is small and in directional drilling, where the collars will likely contact the side of the hole, to minimize differential sticking.

Collars with spiral grooves help prevent differential sticking by reducing the amount of drill collar surface area that contacts the sides of the hole. Differential sticking is a condition in which the drill stem becomes stuck against the wall of the wellbore because of  the difference in pressure between the drilling fluid in the wellbore and that of a permeable formation. The pressure is higher in the wellbore. Thus, the differential pressure forces some of the liquid part of the drilling fluid into the permeable formation.

the difference in pressure between the drilling fluid in the wellbore and that of a permeable formation. The pressure is higher in the wellbore. Thus, the differential pressure forces some of the liquid part of the drilling fluid into the permeable formation.

This leaves a layer of concentrated mud solids on the sides of the hole. This layer of mud solids is called filter cake. The lower formation pressure creates suction that holds the collar against the side of the hole. If the pressure differential between the wellbore and the formation is sufficient and the clearance between the drill collar and the hole is small, it is easy for the collar to contact the filter cake and get stuck.

Square Collars

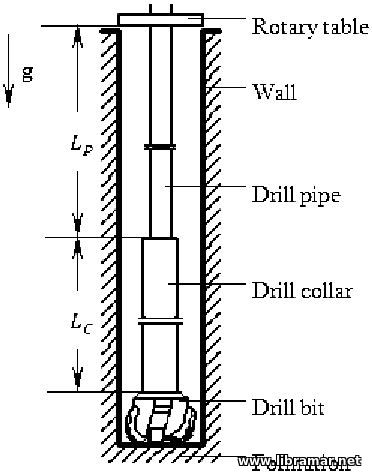

Drillers use square drill collars in an effort to keep the wellbore on as vertical a path as possible. In straight-hole drilling, the driller attempts to keep the wellbore as vertical as possible until the target is reached. One phenomenon that assists the driller is the pendulum effect, or the tendency of the drill stem to hang in a vertical position because of the force of gravity pulling on the weight of the drill collars. The heavier the drill collars, the greater the pendulum effect.

Square drill collars have more steel and are thus stiffer and heavier than round ones. They tend to give, or bend, less than round collars and produce a greater amount of pendulum force. Also, each corner of a square drill collar touches or nearly touches the wall of the hole as the drill stem rotates. This contact (or near contact) acts to stabilize the collar, or keep it stiff and straight. With no wobble, the collar keeps the bit drilling on course.

So these are the main special designs of the drill collars. As it was mentioned earlier, there are several other types of collars produced by the manufacturers, each of them having specific features, and they will be applied by the well planner depending on the characteristics of the particular well.

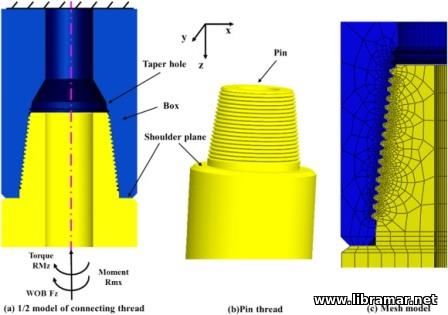

An important factor to consider when connecting collars is the relationship between the pin and the box. Engineers have learned to compare the bending strength of the pin near its base, i.e. near the last engaged pin threat referred to as LET, to the bending strength of the box near its bottom. In good design, the bending strength of the box should be 2.5 times greater than the bending strength of the pin.

An important factor to consider when connecting collars is the relationship between the pin and the box. Engineers have learned to compare the bending strength of the pin near its base, i.e. near the last engaged pin threat referred to as LET, to the bending strength of the box near its bottom. In good design, the bending strength of the box should be 2.5 times greater than the bending strength of the pin.

surface to the bottom of the hole. They are constructed somewhat differently, however, because they fulfill different functions.

surface to the bottom of the hole. They are constructed somewhat differently, however, because they fulfill different functions.