Shipboard Machinery Alarms and Protection Devices

We all understand that the failure of the shipboard machinery may and will result in avoidable and expensive disasters. Do they occur due to bad design, inadequate maintenance or incorrect operational procedures? Experience shows that a large number of machinery breakdowns occur due to a mistake in operation and maintenance of the alarm systems and protection devices.

Yes, engines, generators, boilers, compressors do break down, sometimes fatally damaged because their alarm systems and protection devices monitoring them have been prevented from working, sometimes deliberately disconnected, sometimes clogged up with paint and forgotten, abandoned without checking for long periods of time.

This, of course, is asking for trouble, when only a little attention by duty engineers could avoid an unforeseen incident resulting in possible injuries to people, machinery breakdowns, upsetting the commercial operation of the vessel, leading to extra work load for ship's personnel. Things can go wrong at any time.

unforeseen incident resulting in possible injuries to people, machinery breakdowns, upsetting the commercial operation of the vessel, leading to extra work load for ship's personnel. Things can go wrong at any time.

The ship's system seems to be reliable because no one can be shown which alarm is working and which is not. This can occur as a result or direct consequence of neglecting the alarm system and protection devices. Now, the search begins - what caused the blackout. How long will it take to get things going again? Why is not standby generator or the emergency generator starting? How long will it take to find the answer? An unscheduled event like this can cause consequential breakdowns as well.

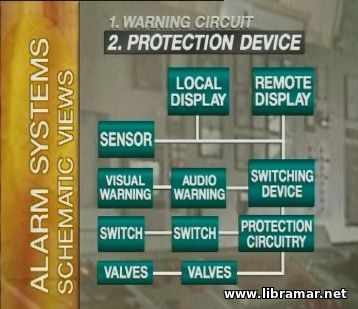

The engineers on board ship must be sure that the alarm systems work properly at all times. There is no other way. Let us leave this nightmare scenario now and look at a schematic view of an alarm and protection system and its function.

A typical alarm circuit has a sensoring device, such as the level or pressure sensor - these are normally connected to display devices which may have minimum or maximum values marked on them. When these values are reached, a switch is activated and an electrical or pressure signal is sent to the ship's alarm panels and audio- or visual warning devices. The light on the panels will remain on or continue flashing until the alarm has been acknowledged by the duty engineer and the condition which has caused the alarm to activate, is removed.

A typical alarm circuit has a sensoring device, such as the level or pressure sensor - these are normally connected to display devices which may have minimum or maximum values marked on them. When these values are reached, a switch is activated and an electrical or pressure signal is sent to the ship's alarm panels and audio- or visual warning devices. The light on the panels will remain on or continue flashing until the alarm has been acknowledged by the duty engineer and the condition which has caused the alarm to activate, is removed.

If it is a protection circuit as well as a warning circuit, the activation of the limit switch also initiates a shutdown procedure of the affected machines, i.e. the protection circuit activates one or more switches or valves causing the protected machine to come to the unscheduled halt. This is how the system looks using an internationally recognized symbols:

A typical example of this system operates on a main engine or on a generator diesel. The sensor may be a lube oil temperature o pressure sensor, or cylinder liner temperature sensor - any one of these may indicate a loss of adequate lubrication which requires rapid reaction to avoid a serious engine breakdown.

With hundreds of installations in the engine room the alarm systems and protection circuits there form a complex monitoring system. There are some vital protection devices as well as some less important circuits. If you came across a faulty sensor, would you know if it was part of a top priority circuit or a relatively less critical one?

All alarm and protection devices that protect the main propulsion engine and the steering system are of top priority, same as the power generator plants and steam boilers - these plants are vital components of ship's control. Any breakdown or serious loss of these functions can be catastrophic. Still very important but not top priority are the alarms and protection devices on the air compressors, air conditioning systems and refrigeration systems.

Other systems such as cargo pump alarms or bow thruster alarms may be low or high priority depending on the ship's working condition. There are warning only alarm systems which do not protect but warn on the potentially hazardous conditions arising. These are normally level indicators or temperature sensors in tanks, heating or cooling systems.

Continued here

The "Read Later" function allows you to add material to this block with just one click. Just click on the icon and read the articles that interest you at any convenient time.