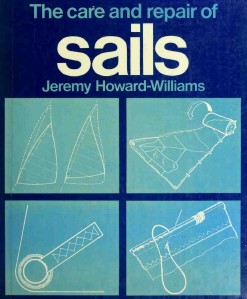

THE CARE AND REPAIR OF SAILS

| Author(s) | Jeremy Howard-Williams |

| Publisher | Sail Books, Inc. |

| Date | 1976 |

| Pages | 139 |

| Format | pdf + epub |

| Size | 13 Mb |

| D O W N L O A D | |

Sails are intricately connected in every aspect to the material from which they are constructed, making it impossible for any book that aims to explore them in detail to overlook the process of sailcloth production and the essential qualities it must possess. The sailmaker invests considerable care and expertise in selecting the cloth for your sail; therefore, it is important to recognize this knowledge when you encounter it, as it is integral to his profession.

Much hinges on his selection, so let us examine some of the factors he must take into account. Sailcloth is typically woven by arranging threads on the loom's beam to create the warp, or lengthwise threads, and then interlacing the thread back and forth over and under the warp to produce what is referred to as the weft.

The resulting weave is compacted by beating the weft, ensuring it lies closely together; the tighter the weave, the greater the cover factor, as the weft causes the warp to crimp. When tension is applied along the warp, the lengthwise threads tend to straighten their crimp and open the weft, which increases the cloth's porosity and diminishes its ability to retain any chemical fillers that may have been incorporated; the individual threads may also slightly untwist and elongate.

However, the stretch is minimal, and no significant deformation of the cloth occurs. Nevertheless, when tension is applied at an angle to the threadline, the small squares created by the weave become distorted into diamond shapes, causing the cloth to elongate in the direction of the tension and narrow across this line.

Consequently, the cloth shifts at right angles to a line of bias tension, resulting in a fold of additional material along this line; the outcome in a sail is increased draft along the tension line and a flattening in the area from which the cloth has been drawn. A quality cloth should not remain permanently deformed after such stress but should return to its original shape once the tension is released.

The "Read Later" function allows you to add material to this block with just one click. Just click on the icon and read the articles that interest you at any convenient time.