Drilling Riser

Semi-submersible rigs have the advantage of being able to move away from a location very quickly, as opposed to a jack up rig. This is a good thing in arctic areas if an iceberg comes rambling down, at 10 miles per hour, strait on collision course with the rig. Semi-submersible rigs are used for exploration, development and sometimes also for production work in deep waters.

Large semi-submersible rigs can be quite self-contained and can operate for long periods without re-supply. They are more like ships in behavior and require additional equipment to control stability in order to function properly.

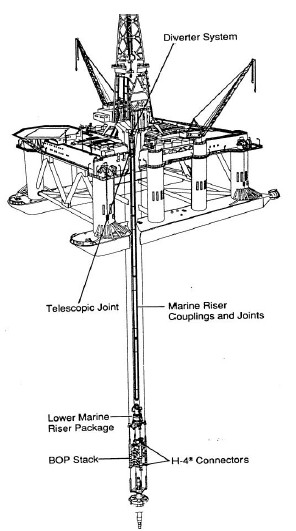

This equipment includes ballast management systems, motion compensators for keeping the drill string on bottom and a riser pipe that isolates the well from the open sea between sea floor and rig. The riser is a set of large pipes which is locked together with seals and bolts in a special way to ensure flexibility and pressure integrity. The riser may have flotation elements attached on the outside to balance the weight of the riser in the water and minimize weight support from rig as this will limit the rigs load capacity.

The Well control equipment (BOP) used on a semi-submersible rig are normally attached to the top of the wellhead at the seafloor. This equipment is remote controlled from the rig through an umbilical or hoses. The main reason for placing the BOP on the sea floor is to prevent high pressure well conditions to enter the riser. As the riser has to be large enough to allow drill string, bit and various casing sizes to pass through, it also has to be strong enough to withstand high well bore pressures. Most risers can hold up to 5000 psi pressure.

There are drilling setups where BOP‘s are located at surface, but then the riser has to have the same pressure rating as the BOP. If the BOP‘s were located at surface, it would be impossible to disconnect at the sea floor as the well would then be open to the environment.

The riser is used as an extension of the well bore from the seabed mounted BOP stack to the floating drilling unit. On a fixed drilling unit, the mandrel and overshot have some of the same functions as a marine riser. It is used for lowering and raising the BOP from the wellhead, to conduct drilling fluid returns to the surface and guide drilling tools down to the seabed. The choke and kill lines mounted on the outer circumference of the riser conduct choke and kill fluids between the BOP stack and choke and kill manifolds.

A Booster line, which is similar in appearance to the choke and kill lines, may be used to conduct drilling mud from the mud pumps down to the riser adapter where it enters the riser. This added volume of drilling fluid in the riser generates a higher annular fluid velocity which insures proper cuttings transport from the well and back up the riser. Cameron offers drilling riser systems which accommodate the stringent conditions encountered in deepwater drilling including high tension loads, multiple control lines, and the need to respond to changes in surface weather conditions.

The LoadKing™ family of riser connectors is designed to meet the demands of ultra deepwater drilling in water depths of 7000 feet or more.

The RF riser connector is designed to meet API 16R requirements with fewer components and higher capacity than other flanged riser connectors.

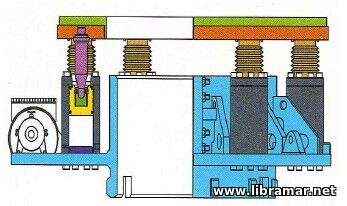

Marine Riser Spider/Gimbal Shock Absorber

The Gimbal Shock Absorber supports the marine riser string while the next joint is picked up and installed.

Reduces impact loads when running and landing marine riser joints.

Hydraulic gate riser handling spider is used when running or retrieving HMF riser joints through the rotary table. Two gates, operated by hydraulic cylinders, support the riser string when the gates are in the closed and locked position.

The MR-6D riser handling spider supports the riser string on manual or hydraulic operating sliding dogs. A positive locking device prevents accidental release.

The Gimbal Shock Absorber supports up to 2.000.000 lbs. and gimbals when the riser is positioned in the spider. Split plates, supported by hydraulic cylinders, form a platform for the riser handling spider and the hydraulic system provides the shock absorbing capability.

Riser Spider

The Shaffer riser spider is designed to support the riser string when running and retrieving through the rotary table. The split-design spider is hydraulically operated, compatible with all rotary tables, and can support up to 3.5 million pounds.

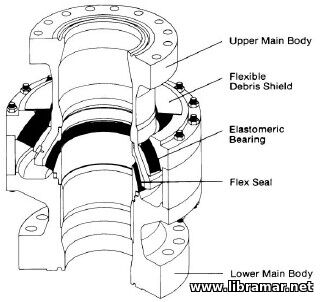

Ball Joint

Ball Joint

• Manufacture: Vetco Gray

• Accommodates 10 deg vertical misalignment

• Minimizes bending loads caused by lateral drilling vessel movement

• Up to one million pounds tensile load capacity

• Pressure balance system compensates for compression and tension loading, minimizing frictional resistance to bending

• Compact sizes accommodate marine riser systems from 16’’ to 24’’ diamete.

Single Flex Joint

The flex joint operates with a single flex element and can accommodate up to 20 degrees including angle of deflection between the marine riser and BOP stack. The SingleFlex has two elastomeric elements. The internal seal element isolates internal fluid and pressure from the bearing element which supports tension and bending loads.

Additional features of the SingleFlex Joint include the following:

• 1.5 million pounds tensile load capacity

• 2.0 million pounds static tensile load capacity

• Rated for 3000 psi internal pressure

• Design eliminates frictional wear, resulting in long service life

• All sliding seals are eliminated static seals between major components

• Minimum maintenance required

• Rated for H2S service and oil-based drilling fluids

• No need for pressure balance

• Available for drilling and production operations

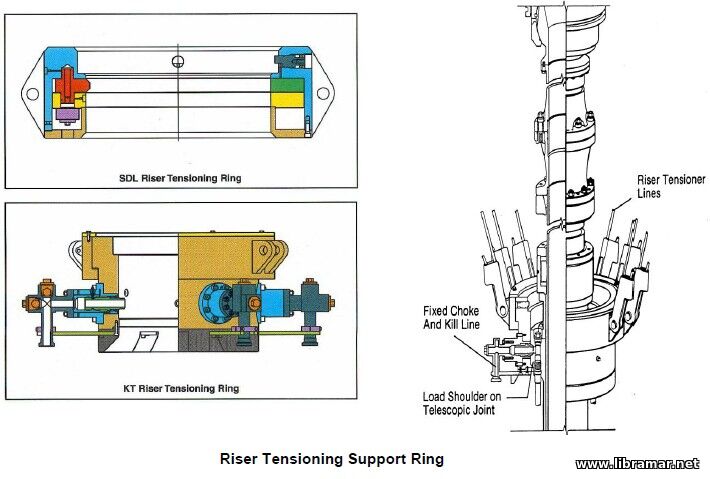

Telescopic Joint

ABB Vetco Gray telescopic joints compensate for heave and offset of the vessel and are available for both type riser systems. Maximum rated riser tensile load capacity in locked position. Hydraulic latch release for inner and outer barrels is available. Dual split/solid packer elements available. Fixed or rotating integral/non-integral tensioner rings. SDL and KT non-integral tensioning ring.

Choke and Kill Line Termination

Choke and kill line termination installed on the telescopic joint outer barrel after the riser system is landed and properly tensioned. This attaches the rig floor manifold piping with high pressure flexible lines and terminal fittings.

Riser Tensioner Rings

Riser tensioner rings form a termination point between the riser tensioner and marine riser system. The non-integral SDL/KT tensioner rings significantly simplify running and retrieving the marine riser by eliminating the tedious and hazardous tasks of make-up/break-out of tensioner lines and hydraulic hoses in the moon pool.

SDL Riser Tensioning Support Ring

Telescopic joint is run and pulled through the rotary table without disconnecting the tensioner lines from the riser tensioner ring. Riser tensioner lines remain properly spaced out at all times.

Hydraulic piping for lockdown/storage dogs remains permanently connected. Hydraulically disconnects from the telescopic joint and locks to a mating profile on the bottom of the diverter housing for convenient, out of the way storage. KT Riser Tensioning Ring, Choke, Kill and auxiliary line terminations are permanently connected. Hydraulic stabs makeup to and breakout from the telescopic joint eliminating a hazardous and time-consuming function. Orientation pins on the ring engage slots in the telescopic joint line termination housing for easy make-up. Permanently installed tensioner lines maintain proper orientation with rig drilling tensioner.

The "Read Later" function allows you to add material to this block with just one click. Just click on the icon and read the articles that interest you at any convenient time.