How you ever noticed the hulls of the ships having a strange protrusion of the forward end? It is big amount of metal sticking out of the water. We call it the bulbous bow. But, it serves a specific purpose. Let us see what the bulbous bows are for and why they are fitted.

All ships are of different sizes and, like the ships, the bulbous bows are also all different sizes. They are all designed specifically for the ship in which they are fitted, and they are all designed to serve one main function.

To understand a bow, let us first consider the vessel which does not have a bulbous bow fitted. As it moves through the water, a pressure wave builds up at the front of the ship. This increases the height of the water – the ship is pushing it ahead; but that water has to go somewhere, so what happens – it flows back down the side of the hull. It will keep flowing back down, forming the wave all the way along the side of the ship’s hull.

Now, the problem with this is that it increases the drag of the vessel. It’s in contact with a larger surface of water, it is coming higher up the hull, the water is moving at the inconsistent speed because it is going up and down as well as along. This increases the fuel consumption of the vessel. So, we need to wind a way to mitigate this wave.

Most of us have seen the ships rolling around. A lot of the time this is down to a failure in one of their systems – the stabilizers. So, how do these stabilizers actually work?

Let us consider a standard cruise ship in calm water. She is going to sit happily upright. Her stability is determined by her center of gravity and her center of buoyancy. As long as they are all lined up in the correct place, she is going to remain upright and stable. If you then introduced some waves to the sea, you are going to start to interact a bit. Smaller waves are unlikely to have much of an impact on a large ship. But, as the wave size increases, the wavelength increases, and you are going to start to feel the ship interacting. She will be rolling from side to side, following the rhythm of the wave, and this is purely down to the fact that as the water level on one side of the ship rises, the ship generates more buoyancy on that side and this results in a force that makes her lean over.

Most of the time a ship will happily just continue riding the waves, rolling gently from side to side. The only exception, of course, is “synchronous rolling” and that is when the frequency of the wave matches the natural frequency of the ship’s roll. This results in rapidly increasing angles of roll until the ship actually capsizes. Apart from that, gentle rolling is not an issue on those ships, but on a cruise ship you expect to be able to have a flute of champagne stay put on a table when you put it down. You do not want the ship to be rolling underneath you, spilling your drink everywhere. issue on those ships, but on a cruise ship you expect to be able to have a flute of champagne stay put on a table when you put it down. You do not want the ship to be rolling underneath you, spilling your drink everywhere.

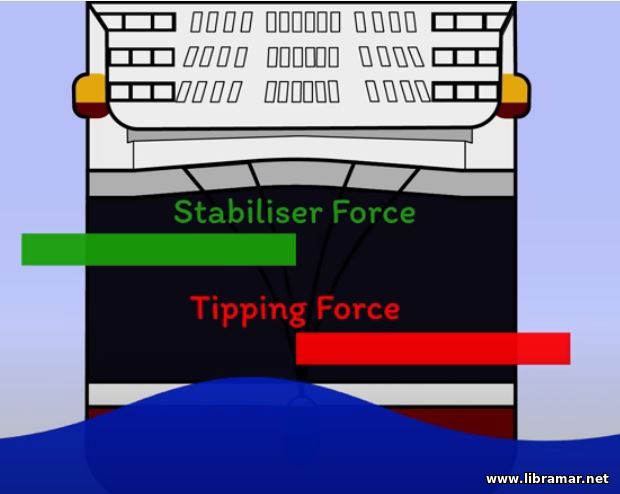

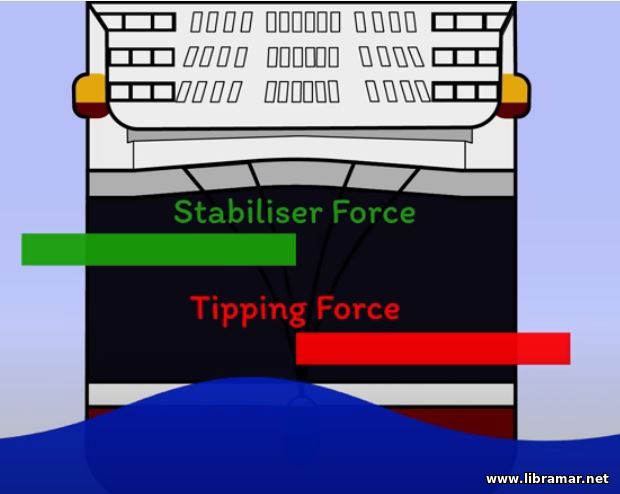

Instead, these ships use stabilizers to minimize that rolling. We want the ship to remain upright while the waves run underneath her. The goal of the stabilizer is to counter the force generated by a wave. Unfortunately, that force is not constant. As the crest of the wave hits one side of the ship, the tipping force is at its maximum. As the wave crest moves through the center line, the force becomes pretty much zero and then, as it moves to the other size, again the force becomes a maximum, but in the other direction.

The stabilizer needs to counter all of that. It needs to be able to change the amount of force it generates, depending on the exact location of the wave, which is constantly changing. To do that, the industry has come up with a few types of stabilizer – they can be split into two categories – active and passive.

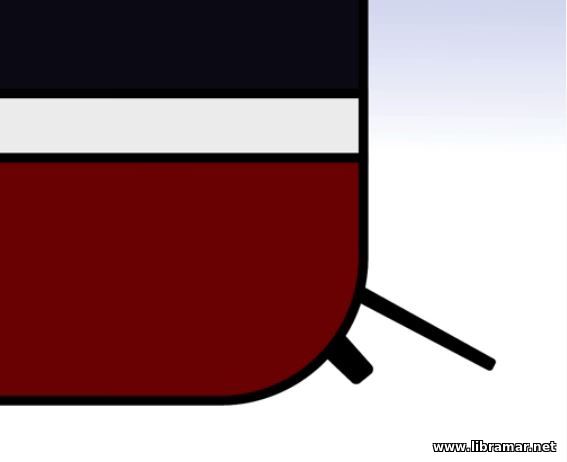

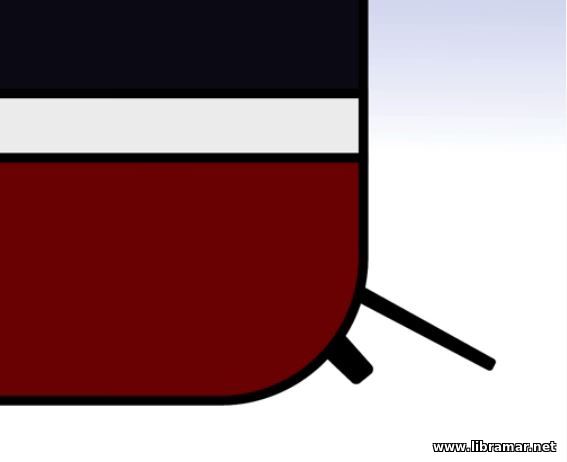

A good example of passive stabilizers are bilge keels. These are protrusions on the bilges of a hull and all they effectively do is dampen any roll. They generate turbulence as they move up and down. To have any effect, they need to apply a force. As they are passive, they can only generate that force when the ship is rolling anyway. Both keels are OK at dampening a roll, and they are very cheap to install so they are a popular design feature on many ships. Unfortunately, they do not do enough to produce a required counter-effect that we need on a cruise ship.

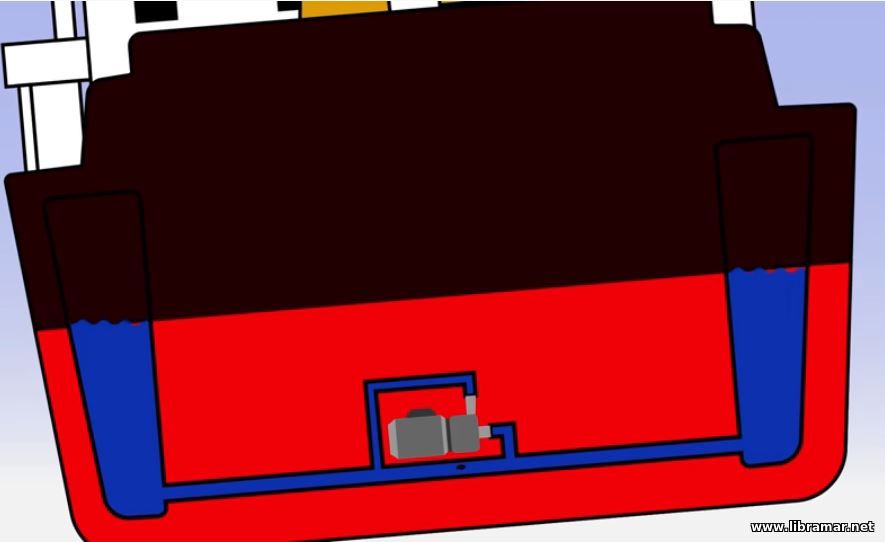

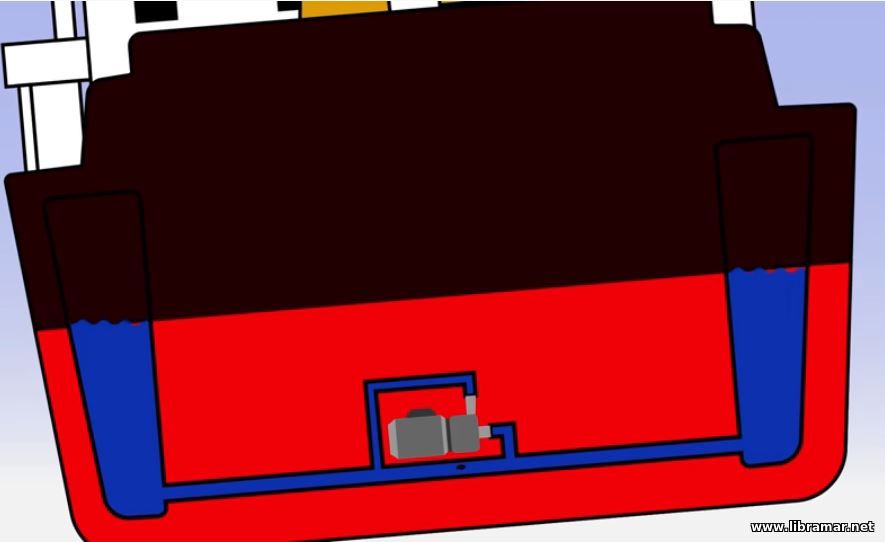

Another level of stabilization is passive anti-roll tanks, installed in the extreme of the ship’s breadth. The key to these is in the  design of the crossover pipes. Normally with the ship upright, they are going to have the same amount of fluid on each side. As the ship leans over one way the fluid in the low side is going to increase. If you can control the flow of fluid enough, you can have the maximum amount of weight in that side as the wave moves across the ship. design of the crossover pipes. Normally with the ship upright, they are going to have the same amount of fluid on each side. As the ship leans over one way the fluid in the low side is going to increase. If you can control the flow of fluid enough, you can have the maximum amount of weight in that side as the wave moves across the ship.

Theoretically, if you keep the fluid there while the wave crest is there, it can help to counter the roll. Of course, you need to release it to let it flow to the other side at just the right time so that it is ready to counter the next wave as that approaches. You can add in more control onto these tanks making them semi-active. Or, you can even add in a set of tanks controlled by a gyroscopic stabilization system that can pump water across whenever it is needed. This would be a fully active system and these stabilizers are good on ships. They would work OK on cruise ships as they can actively counter the force of the roll as it is happening. Unfortunately, it does take time to pump water across so you still have not achieved instant stabilization.

For that, we are left with the fin stabilizer – this is actually the most common form of stabilization encountered on cruise ships. The system basically consists of a hydraulically operated wing that extends out underwater. You will notice it looks similar to the bilge keels discussed above. The main difference is that with these active fins you can change the angle of attack. Looking at the side profile of a fin, you will see what happens when it rotates: turn it one way and the water flow will produce a huge force in one direction, turn it the other way and you have instantly swapped the direction of that force.

With the correct gyroscopic control, you just need to rotate the pin in such a way that it counters the force generated by the wave that is trying to roll the ship. Indeed, you can even use it to encounter a roll generated by other forces like wind or even internal movement of people or cargo. The main disadvantage of these fins, though, is that they are only going to work while the ship is actually moving. They need a water flow across them. Below a certain speed, usually six knots, the water flow is not actually enough to generate a sufficient righting force. Luckily, most cruise ships have a minimum speed well above this, anyway, so it is not actually an issue when they are on passage. This is why cargo ships with their generally lower speeds do not typically install active fin stabilization. Saying that, there are container vessels that do, but only ones where their typical speeds are high enough to get the maximum benefit.

So, next time you are sipping your champagne in a high sea, just spare a thought to the technology that is going into keeping your glass from sliding off the table.

General

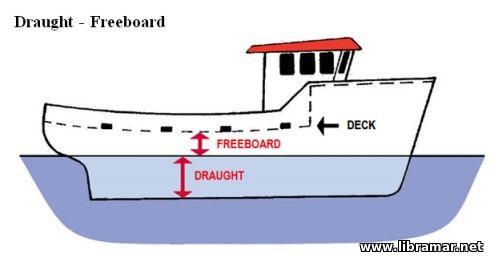

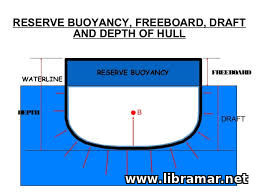

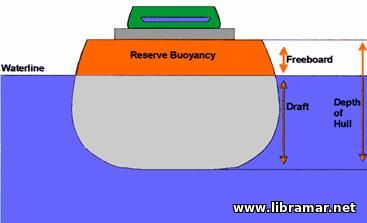

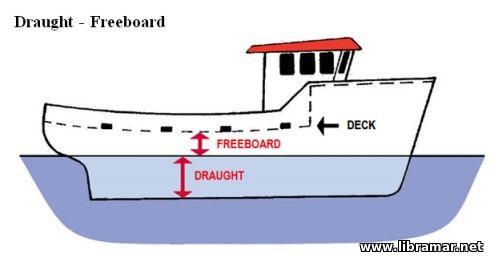

The minimum freeboard that can be assigned to a vessel is that derived from the regulations depending upon the dimensions and characteristics of the vessel. The actual maximum operating draft permitted may coincide with minimum freeboard or it may be set by other federal regulations developed as a result of U. S. law or by international agreements such as the subdivision regulations in the 1973 Oil Pollution Convention, the IMCO Chemical Code or Gas Code.

Within the load line regulations the minimum freeboard may be affected by ship geometry, hull structure or stability. In no case can a freeboard less than the minimum geometric freeboard be assigned even though the scantlings of the vessel are heavier than required for the draft and the stability in excess of that required by an Administration for the intended freeboard.

Freeboard Tables

The tables issued for freeboard are based upon a comparison with a rule vessel having a standard sheer, length-to-depth ratio, block coefficient and reserve buoyancy. Adjustments are made for variations from the standard ship and there are different tables for different types of vessels.

Strength of Hull

The regulations assume that the strength of the vessel is satisfactory for the draft corresponding to the freeboard assigned.  Ships which comply with the highest standards of a classification society recognized by the Administration are regarded as having sufficient strength for the minimum freeboards allowed under the regulations. Ships which do not comply with the highest standards of a classification society are to be assigned such increased freeboards as are determined by the assigning authority. The corresponding draft in such cases is often referred to as a scantling draft Ships which comply with the highest standards of a classification society recognized by the Administration are regarded as having sufficient strength for the minimum freeboards allowed under the regulations. Ships which do not comply with the highest standards of a classification society are to be assigned such increased freeboards as are determined by the assigning authority. The corresponding draft in such cases is often referred to as a scantling draft

Protection of Crew

It should be noted that while the freeboard assigned is based primarily upon reserve buoyancy, the question of a suitable height of platform for the safe working of the vessel by the crew is automatically dealt with at the same time. Protection for the crew, in the strength of houses, gangways, guard rails, life lines, and the height of working platform itself, is a very important concern of the load line regulations and specific regulations are provided for each.

Stability

The original International Convention on Load Lines, 1930, presumed that specific stability approval was not a concern of the regulations. At that time it was assumed that those responsible had seen to it that the "nature and stowage of the cargo, ballast, and so on, are such as to secure sufficient stability for the ship."

The present Convention (ICLL, 1966) has reversed the position of the earlier Convention by including a specific regulation worded such that stability information must be provided the master of every new vessel, "in an approved form to give him guidance as the stability of the vessel under varying conditions of service." This requirement has been interpreted quite firmly by the U. S. Coast Guard to include an inclining test for almost all U. S. commercial ships, a full stability evaluation based on the inclining, and an official stability letter issued by them as a condition necessary to issuance of the official load line certificate. Many other administrations follow a similar procedure.

Passenger Ship Subdivision

A vessel engaging in international voyages and carrying more than twelve passengers is governed by a separate regulation.  Internationally, a load line is assigned and marked depending upon a subdivision and damage stability analysis of the ship under the applicable regulations of the SOLAS, 1974. Under U. S. regulations for certain ships, depending upon size or other limitations, a subdivision and damage stability examination is required if six or more passengers are carried. In no case may this subdivision load line be placed higher on a ship's side than the load line permitted under the load line regulations. Internationally, a load line is assigned and marked depending upon a subdivision and damage stability analysis of the ship under the applicable regulations of the SOLAS, 1974. Under U. S. regulations for certain ships, depending upon size or other limitations, a subdivision and damage stability examination is required if six or more passengers are carried. In no case may this subdivision load line be placed higher on a ship's side than the load line permitted under the load line regulations.

Geometry of Vessel

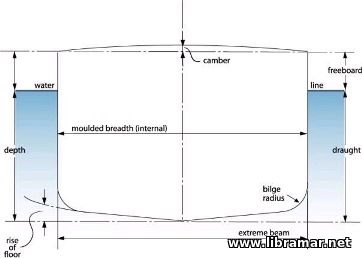

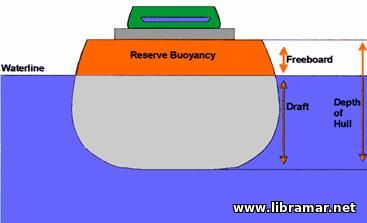

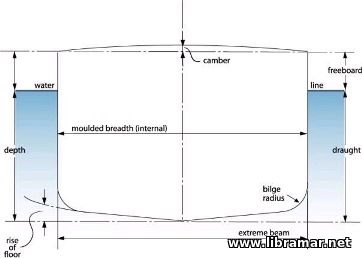

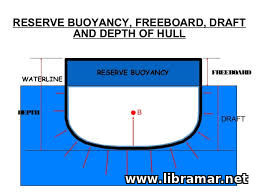

The minimum freeboard is designed to provide a standard of reserve buoyancy (the volume of the watertight hull above the load waterline) that has been found by experience to be satisfactory in service. This minimum freeboard is based upon the geometry of the vessel. A comparison is made of the block coefficient, the length-to-depth ratio, bow height, and the sheer of the vessel with those of a standard vessel of the same length.

Corrections are made to the basic freeboard, predicated on the length of the vessel, depending upon how these particulars vary from those of the standard vessel. Deductions are made from the freeboard depending upon the length of superstructures and the character of the closures in their end bulkheads. The resulting freeboard gives a height of working platform and a proportion of reserve buoyancy equivalent to that on vessels which have proven satisfactory in service.

Both camber and sheer play a part in clearing water rapidly from the decks, but only sheer corrections to freeboard are made depending upon the differences in sheer from the standard. Since there is no standard for camber in the 1966 Convention, no adjustment need be made.

Superstructures can contribute to reserve buoyancy and offer protection to openings in the hull at the level of the freeboard deck under certain conditions. Deductions are made from the freeboard for these special superstructures depending upon the efficiency of the protection provided for access openings in the end bulkheads.

Detached superstructures are also a consideration because there are differences in the deductions for superstructures depending upon their length and location. While the regulations do not require that a forecastle be fitted, a minimum height of the bow above the summer load water line is specified. In lieu of a forecastle the required bow height can be obtained by increasing the sheer curve of the main deck.

Openings in the Hull and Superstructure

A most important consideration in the assignment of freeboard is the protection of openings in the hull and superstructures, such as hatches, ventilators, air pipes, scuppers, overboard dis¬charges, and the access openings in the end bulkheads of superstructures. Standards are laid down in the regulations for these, and the assigning authority must be satisfied with their efficiency before a minimum freeboard is assigned. The safety of the vessel depends far more upon their satisfactory maintenance than in any small differences in the freeboard assigned.

In one of the previous articles we have given some brief Introduction to the Load Lines and Conditions of the Load Line Assignment. As we all know, the assignment of the shipboard load lines and associated requirements are listed in the International Convention on Load Lines of 1969. Today, let us check what were the changes and developments that eventually led to the need for the subject governing document.

Need for a Standardized System

The need for a standardized international system of tonnage measurement of ships is evidenced by the fact that small ships of identical size and form may measure less than 200 gross tons or more than 1000 gross tons and the fact that exemptible and deductible spaces are treated differently under various national rules. The variations in tonnages cause inequities in the assessment of charges and in the application of provisions of treaties and laws.

This need for a standardized system was recognized in tin initiation of the League of Nations study and in the Oslo Convention.  However, there were many differences in national systems and in those systems evolving from tin foregoing international activities that were yet to be resolved. However, there were many differences in national systems and in those systems evolving from tin foregoing international activities that were yet to be resolved.

Work by the Intergovernmental Maritime Consultative Organization

In the meantime, the question of tonnage measurement had often been discussed by the Transport and Communications Commission of the United Nations. After the Intergovernmental Maritime Consultative Organization (IMCO) came into being in 1958, the task of developing a universal system of tonnage measurement of ships was taken over by the Organization as the United Nations had intended.

Against this background, IMCO formed a subcommittee of its Maritime Safety Committee in 1959 to study the problem and to draw up recommendations for a system of tonnage measurement suitable for worldwide application, which would be just and equitable between the individual ships and groups of ships, and would not hamper good design or mitigate seaworthiness, and which would take account of the economics of the shipping industry generally.

Over a period of years, the Subcommittee and its working group considered a number of proposals for a universal system of tonnage measurement. Finally the International Conference on Tonnage Measurement of Ships, 19G6, was held in London during a  four-week period beginning May 27, 1969. four-week period beginning May 27, 1969.

The Conference adopted the International Convention on Tonnage Measurement of Ships (ICTM, 1969), which the delegations felt largely met the above-listed criteria for a satisfactory system.

Tonnage measurement rules generally are spelled out in great detail in national laws. More detailed criteria for application of the laws are spelled out in regulations. The laws and regulations are interpreted by administrations established for the purpose. Since tonnages are used to determine the applicability of provisions of treaties, laws, and regulations and as bases for assessing charges, fees, and duties, any change in rules that would result in substantially different tonnage assignments for many vessels would disrupt the shipping industry. Historically, administrative decisions and rule changes have favored the ship owner, probably, because other segments of the shipping industry can protect their individual interests merely by changing rates for charges or by adopting parameters other than tonnages.

Transition from Deadweight to Volumetric Tonnage

The use of one half the breadth for the draft in the formula for approximating deadweight in the system preceding the Moorsom system led owners to acquire vessels that were poorly designed to obtain official tonnage assignments that were making the register tonnage a simple function of the volume of a vessel, the British opted for a coefficient (1/100) that would, on the average, slightly reduce the existing tonnages instead of opting for a coefficient that would more precisely approximate the deadweight.

The reasoning apparently was that if a system yielding higher, more precise deadweight tonnages were adopted, ship owners would find them burdened with higher bases for being assessed charges with no assurance that charging authorities would correspondingly reduce their rates. Other governments in amending their laws followed the example set by England. While the philosophy of avoiding radical changes in the tonnages assigned merchant vessels continues, governments can be persuaded to  make their rules more logical. make their rules more logical.

In seeking a universal tonnage measurement system, the International Conference on Tonnage Measurement held in London in 1969 decided to do away with the system of exemptions and deductions from gross tonnage. The conference adopted a formula that would yield gross tonnages closely approximating those of vessels measured under present national rules without exemptions for shelter 'tween decks, deck spaces opened by tonnage openings, passenger spaces, and water-ballast spaces. On the other hand, the conference decided to maintain the net tonnage advantage enjoyed by shelter deck types and to extend that advantage to other types of vessels having low draft to depth ratios. That decision has already caused some charging authorities to shift their charge bases from net tonnage to gross tonnage.

Resistance to Illogical Changes

With varying degrees of success, governments have, at times, resisted illogical rule changes forced upon or willingly adopted by administrations of other governments. National rules usually provide that a space outside the double bottom adapted only to carry water ballast shall be included in the gross tonnage and deducted to arrive at net tonnage. They also provide that a space above deck shall be included in the gross tonnage if it is closed in and is available for the carriage of cargo or stores or for the berthing or accommodation of passengers or crew.

The United States adopted the Moorsom system by an Act of Congress dated May 6, 1864. That act specifically required passenger spaces to be included in the register tonnage. By an act dated February 28, 1865, however, the U.S. provided for the exemption of passenger spaces on or above the first deck which is not a deck to the hull. Only Liberia and Panama have followed that example. Pursuant to a law enacted February 6, 1909, until 1915 the U.S. included in the gross tonnage then deducted to arrive at net tonnage space adapted only for carrying water ballast out¬side the double bottom.

General

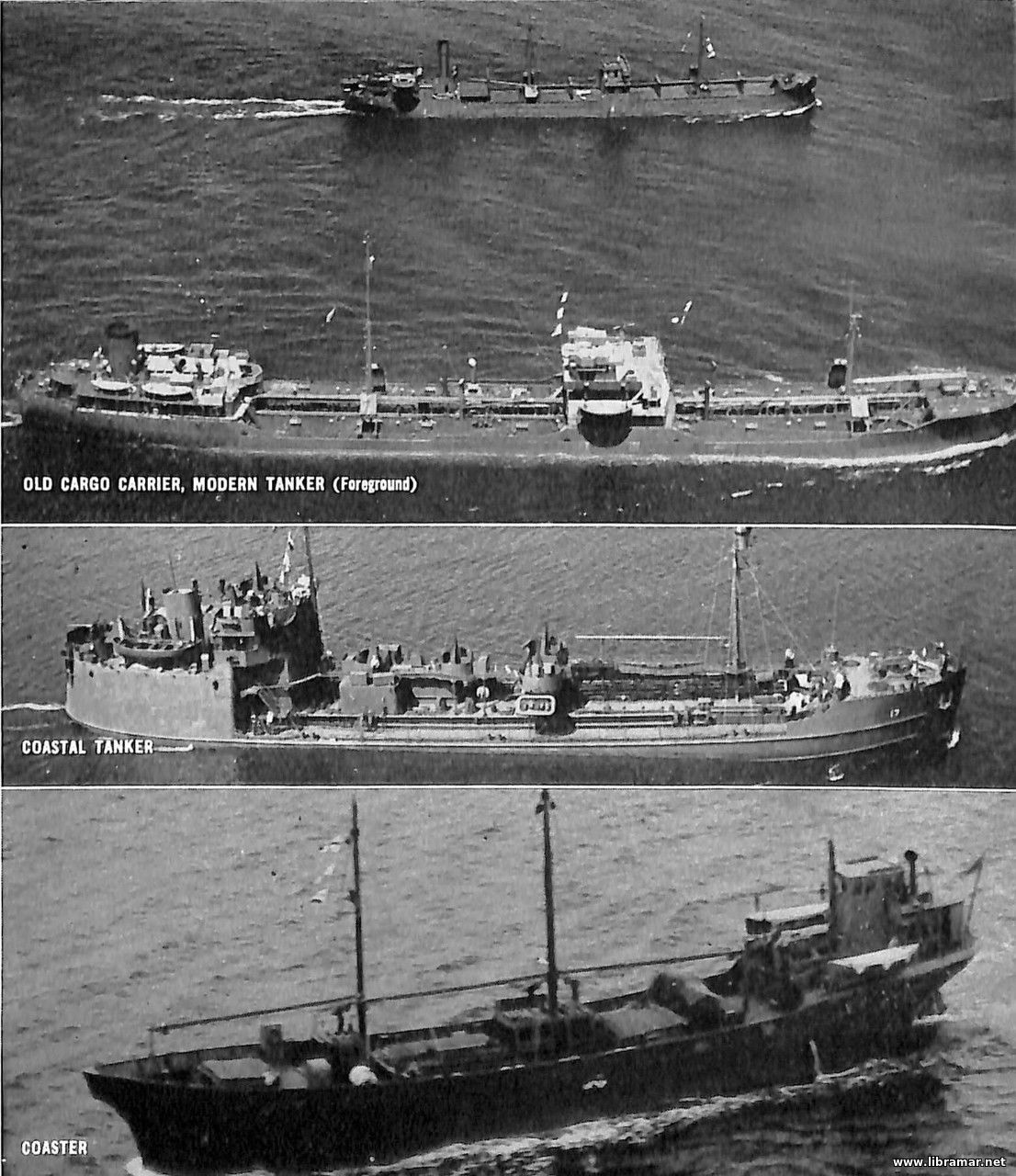

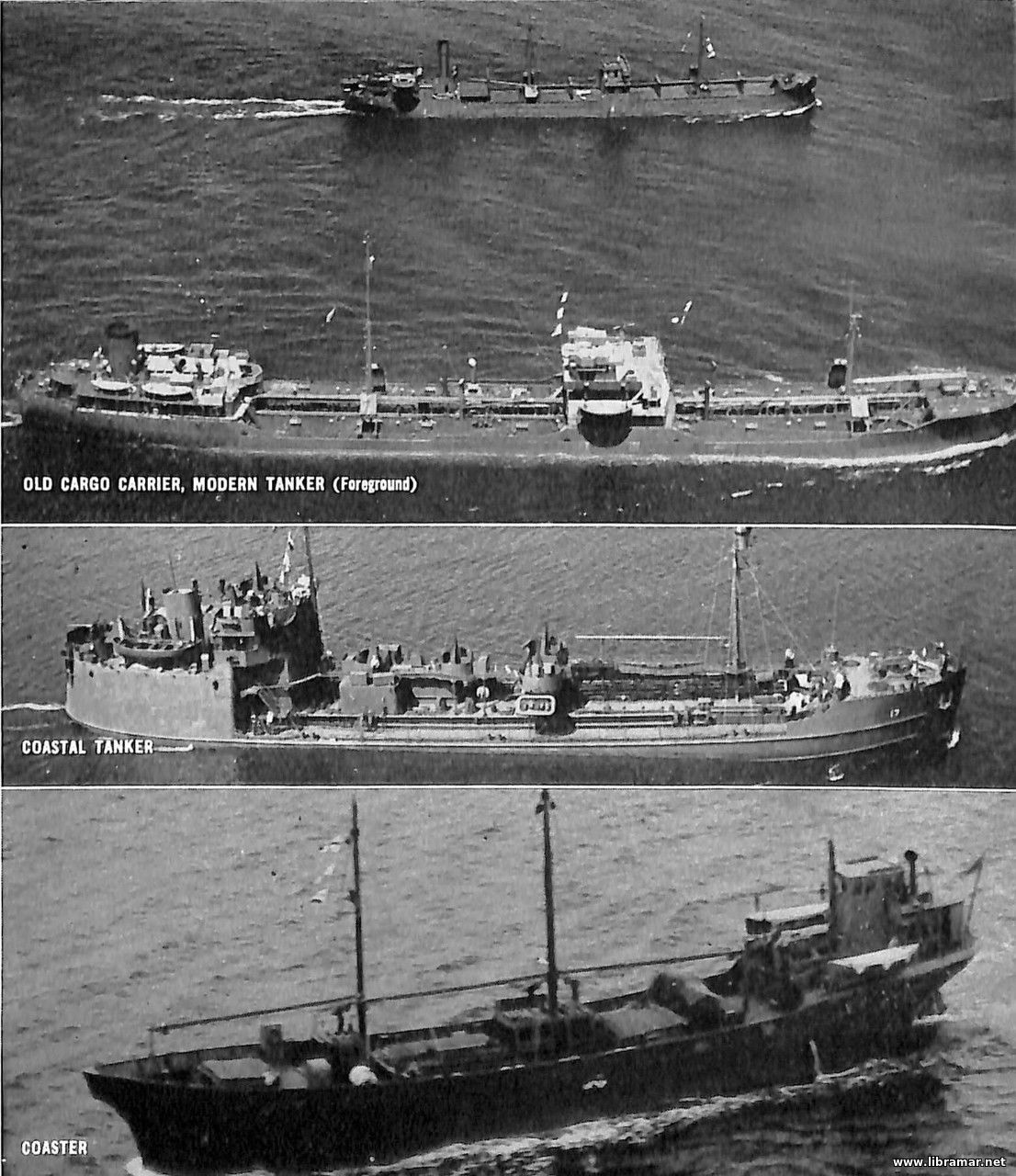

The most important area for load line improvement is that concerning the non-standard ship. Such ships might be treated casually by signatory nations but for two factors of great impact. The first factor is the legal realization that the International Load Line Convention, 1966 is the most widely applicable marine convention, since it requires a load line on every floating object with a horizontal dimension greater than 24 m unless it is a warship, fishing vessel or yacht. The second factor is the realization that the number and variety of ships which do not carry cargo in a weathertight interior have been increasing. Therefore, it is of some importance to outline these differences and explore those parts where new international agreement is needed most.

Let us examine those areas in which some of the new non-standard ships must be treated differently than the standard ship. First consider offshore drilling units. These can be subdivided into three general categories: Drillship, jack-up, and semi-submersible. The ship type fits the L/D, СB, and sheer of a standard ship but may not be fully maneuverable in a storm; therefore, sheer and bow height requirements are not utilized as contemplated by the Convention.

The jack-up type is a barge with limited stability while under tow and is also usually lacking in sheer and bow height. A semi- submersible has an L/D of no use in the strength evaluation, a very small СB so as to be transparent to waves, and no need for sheer nor bow height since normally the weather deck may be between 9 m and 30 m above the water whether under tow or drilling. Its loading capacity is often stability limited and it is essential for survival that no wave ever impact fully on the upper structure. While all of these types can be prepared for storms of various degrees of intensity, they are all dependent on advance weather warning for survival. submersible has an L/D of no use in the strength evaluation, a very small СB so as to be transparent to waves, and no need for sheer nor bow height since normally the weather deck may be between 9 m and 30 m above the water whether under tow or drilling. Its loading capacity is often stability limited and it is essential for survival that no wave ever impact fully on the upper structure. While all of these types can be prepared for storms of various degrees of intensity, they are all dependent on advance weather warning for survival.

Surface-effect ships and hydrofoils need two separate evaluations as to their ability to weather a storm at sea. The first is in the waterborne mode and the second is in the out-of-water mode which involves high-speed interaction with waves and wind. In the latter mode, L/D, СB, sheer, etc., are essentially meaningless in the sense of the standard ship seakeeping evaluation assumed by Load Line Regulation.

High-speed planing hulls also defy the theory of sea-keeping in the sense of the standard ship, having a varying relation of Св and sheer to the seaway since their speed changes their displacement.

Catamarans and other multi-hull ships have no direct relation to Св, while ocean mining ships and pipe-laying barges are moored at a fixed heading allowing little opportunity to utilize bow height sheer effectively by turning into a storm sea. Catamarans and other multi-hull ships have no direct relation to Св, while ocean mining ships and pipe-laying barges are moored at a fixed heading allowing little opportunity to utilize bow height sheer effectively by turning into a storm sea.

Semi-submersible ships are now being built for several different services, some of which envision submerging at sea; this, incidentally, being prohibited by the Load Line Convention. Their purpose is primarily for the carriage of continental shelf equipment, heavy industrial items, and other barges.

If these ever engage in submerged operations while at sea, they must be designed to certain limits in obvious contradiction of the Load Line Convention and the government of registry must report the design limits to IMCO.

Solution

Thus far, the solution to finding a proper load line for these non-standard ships has been a separate evaluation of each design in the proposed maximum seaway conditions by the designer himself. Since a pure textbook solution to many of these problems is not feasible, it often means a series of intricate and expensive model tests to determine within generalized limits the adequacy of the design and geometric parameters for safety at sea.

In order to find the best approach to overall safety at sea for each of these non-standard ships and at the same time retain the value of the Load Line Convention as a legally acceptable certificate of evaluation for seaworthiness around the world, there is a need for further international agreements. This can be accomplished as a series of special codes or as additional annexes to the Convention; however, it remains to be seen if the many different types of non-standard ships can be successfully generalized.

Generalizing the large numbers of non-standard ships may be done in a variety of ways. Legally, in order to retain for all vessels  the general safety foundation established for ship-shaped hulls by the Convention, it may be necessary to drop the definition of international voyage now used and to substitute a definition which includes operation on and exposure to the sea anywhere in the world as both standard and non-standard ships have a need for the governmental protection offered by the Load Line Convention. the general safety foundation established for ship-shaped hulls by the Convention, it may be necessary to drop the definition of international voyage now used and to substitute a definition which includes operation on and exposure to the sea anywhere in the world as both standard and non-standard ships have a need for the governmental protection offered by the Load Line Convention.

As a function of design, they may be categorized by differences in form, geometry, stability, and seakeeping limits. Regarding service, they may be categorized by type of cargo, length of voyage or area of operation. Finally, it is evident to the authors of this chapter that non-standard ships will be proliferating and will most certainly be operationally limited by the Administrations until research and development has progressed to a point where administrations can predict the effect of seaway operation on these ships and will therefore permit wider latitude in their use

General

The freeboard can be limited in several ways, such as:

- The numerical calculation of ship's geometry;

- The structurally limited design draft;

- Stability limitations.

Another method of fixing draft, hence limiting freeboard, is by requiring a particular level of subdivision safety for the ship.

Although subdivision is not actually required by the In¬ternational Convention on Load Lines, the Convention does recognize subdivision as one of the several reasons for allowing tankers a reduced freeboard and permits other ships properly subdivided to approach tanker.

As a load line matter, subdivision is somewhat controversial from two points of view. The first is the fact that some national administrations require the subdivision calculation only at the load line draft. The second difficulty sometimes expressed is that the freeboard assigned to the ship is automatically spoken of as reserve buoyancy without an examination of the internal bulkheading in the ship. Since bulkheading is not actually required for load line purposes, there are ships which do not have adequate internal compartmentation to qualify for any degree of subdivision.

The bulkheading that exists in many ships provides an unknown level of subdivision safety which can only be assessed by calculation. When any loss of buoyancy occurs, the ship must depend for its survival on the volume of ship above the normal waterline, which is not a part of the flooded portion of the ship. Thus, part of the same volume that is used for reserve buoyancy of an intact ship in a seaway earlier in this chapter is now used for protection against sinking from loss of internal buoyancy. This could be termed residual buoyancy.

There is an important distinction between the two types of buoyancy. Reserve buoyancy for seakindliness and safety in a storm  is considered fully intact at all times and the crew of the ship is responsible for properly maintaining all closures in order that this buoyancy remains effective against the sea. Residual buoyancy for resistance to flooding is, by definition, a matter of internal compartmentation of the hull. is considered fully intact at all times and the crew of the ship is responsible for properly maintaining all closures in order that this buoyancy remains effective against the sea. Residual buoyancy for resistance to flooding is, by definition, a matter of internal compartmentation of the hull.

The hull may lose some or all of its watertight integrity at any time due to stranding, collision, shell fracture, fire-fighting action, ruptured seawater piping, loss of hatch covers, etc. The rationale for subdivision is not to provide an unsinkable ship. The folly of that idea should have been permanently established with the loss of the Titanic, some seventy years ago. Instead, subdivision is used to provide a level of safety which enhances the probability of survival from flooding or prolongs the time for damage control action to be taken by the crew or by ship salvage crews and finally provides extra time for the people on board the ship to be safely removed if this becomes necessary.

For ships required to have load lines which also require a subdivision analysis, a check is made to ascertain that the permissible geometric load line draft does not exceed the subdivision draft.

Passenger Ship Subdivision Load Lines

The Inter¬national Convention for the Safety of Life at Sea requires that every ship carrying more than 12 passengers on an international voyage must be examined and must satisfy a particular level of subdivision. The level required for each ship is set by formula and is dependent upon the number of passengers which the ship intends to carry and the length of ship.

There are two ways to approach this subdivision draft. The first is via Fart В of Chapter II of the 1974 SOLAS Convention. The second is through the use of an alternative method explained and contained in IMCO Resolution A.260(VII). It utilizes the same basic parameters of persons, that is, passengers and crew, and length of ship. However, additional factors have been considered based on probable statistical occurrence of damage.

Factors from previous casualties such as damage position along the length of the ship, extent of damage, existence of longitudinal bulkheads, loading and permeabilities, sea states, and finally a corroboration of formulas by model test were all used to decide the final format and coefficients for the formula replacing the SOLAS 1974 method of determining compliance. The advantages of the new method are principally that established shipbuilding techniques, such as longitudinal bulkheading, which were not creditable under SOLAS 1974 are now officially recognized in the formulas as a subdivision asset. Also, greater latitude in internal bulkhead arrangements can be accounted for. Factors from previous casualties such as damage position along the length of the ship, extent of damage, existence of longitudinal bulkheads, loading and permeabilities, sea states, and finally a corroboration of formulas by model test were all used to decide the final format and coefficients for the formula replacing the SOLAS 1974 method of determining compliance. The advantages of the new method are principally that established shipbuilding techniques, such as longitudinal bulkheading, which were not creditable under SOLAS 1974 are now officially recognized in the formulas as a subdivision asset. Also, greater latitude in internal bulkhead arrangements can be accounted for.

In addition to the international rules for subdivision, which apply to all passengers ships making international voyages. United States regulations require subdivision calculations for all passenger ships on the navigable waters of the United States, whether on foreign, coastwise or Great Lakes voyages, or for ferryboats on inland waters.

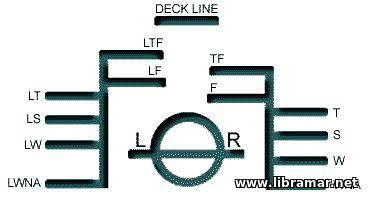

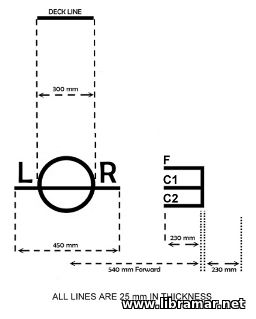

Freeboard Marks

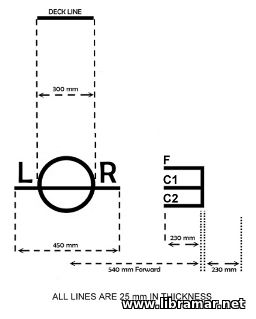

After the application of all the corrections to the basic Minimum Summer Freeboard are made, the result is the Minimum Summer Freeboard in salt water which will be assigned to the vessel. This freeboard may in no case be less than 50 mm. For ships having hatchways with covers other than steel or equivalent material on the freeboard deck or on superstructure decks situated forward of a point located a quarter of the ship's length from the forward perpendicular, the freeboard is not less than 150 mm.

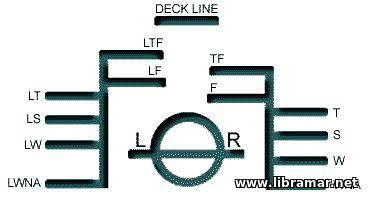

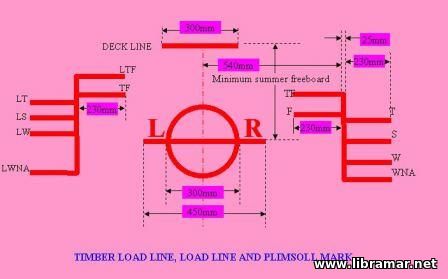

Load Line Format

The freeboard is measured from the top of the deck amidships to the top of the line through the center of the load-line ring. Forward of the ring is a grid composed of lines indicating the maximum loadings in fresh water and for the different seasons, including the summer line which will be at the same level as the center of the ring.

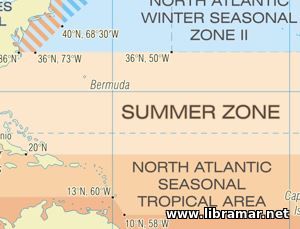

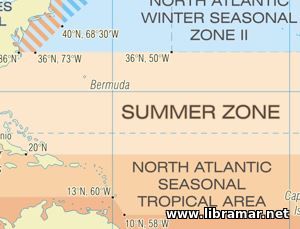

Zones and Seasons

The regulations require a vessel to be so loaded when departing upon a voyage that at no time during any portion of the voyage will the applicable seasonal mark be submerged. The oceans of the world are divided under the regulations into various zones and seasonal areas according to the probable severity of the weather. In certain areas and times of the year where during the winter more severe weather may be expected the vessel is required not to load as deeply as is permitted in the summer.

These areas are the seasonal winter zones, and the times of the year when the winter mark is applicable are shown on a map attached to the regulations. During other times of the year, the summer mark at the center of the ring is applicable. Other zones, roughly corresponding to the temperate zone in the northern and southern hemispheres, are permanent summer zones under the regulations where the summer mark is applicable the year around.

Another zone, on either side of the equator, is a permanent tropical zone where the anticipated weather is generally less severe than might be expected in the summer in the temperate zone. In these zones vessels are permitted to load somewhat deeper any time during the year. Other areas between the permanent summer and tropical zones arc considered one or the other at specified different times of the year.

Calculation of Seasonal Marks

The various seasonal and fresh water marks are obtained as follows:

Tropical Freeboard Mark (T)

The line to mark the maximum loading in the tropical zone is obtained as a deduction from the Summer Freeboard of one forty-eighth of the summer draft measured from the top of the keel to the center of the ring. Again, the freeboard must not be less than 50 mm or 150 mm.

Winter Freeboard Mark (W)

The line to mark the maximum loading in winter zones is obtained by an addition to the Summer Freeboard of one forty-eighth of the molded summer draft.

Winter North Atlantic Freeboard (WNA)

The minimum freeboard for ships of not more than 100 m in length which enter any part of the North Atlantic defined in the regulations during the winter seasonal period shall be the winter freeboard plus 50 mm. For other ships, the Winter North Atlantic Freeboard shall be the winter freeboard.

Fresh-Water (F and TF)

The regulations apply to vessels at sea in salt water. An allowance is computed as a guide in compensating for deeper draft when a vessel loads in fresh water. The fresh water allowance in cm is determined by dividing the displacement at the summer load waterline by forty times the tons per cm immersion at the draft. The fresh-water allowance in inches is determined by dividing the summer load line displacement by forty times the tons per inch immersion at that draft.

If the basic information is not available, the allowance is taken at one forty-eighth of the summer draft. The fresh-water allowance applies to all seasonal freeboards, but fresh-water lines arc marked on the vessel only for the summer and tropical conditions. Where the water is brackish, a proportion of the fresh-water allowance is used, and a measurement of the actual density of the water at the place of loading may be required.

Steaming Allowance

In addition to the fresh-water allowance, deeper loading is also permitted to allow for consumables used between the point of loading and the open sea.

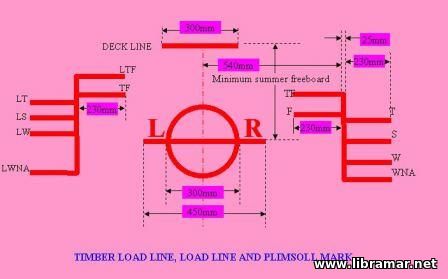

Timber Freeboards Timber Freeboards

If a Timber Freeboard is assigned it is marked in addition to the ordinary load lines with some slight variation. The Winter Timber Freeboard is obtained by adding to the Summer Timber Freeboard one thirty-sixth of the molded summer timber draft. The Winter North Atlantic Timber Freeboard is not to be less than the ordinary Winter North Atlantic Free¬board.

|

issue on those ships, but on a cruise ship you expect to be able to have a flute of champagne stay put on a table when you put it down. You do not want the ship to be rolling underneath you, spilling your drink everywhere.

issue on those ships, but on a cruise ship you expect to be able to have a flute of champagne stay put on a table when you put it down. You do not want the ship to be rolling underneath you, spilling your drink everywhere. design of the crossover pipes. Normally with the ship upright, they are going to have the same amount of fluid on each side. As the ship leans over one way the fluid in the low side is going to increase. If you can control the flow of fluid enough, you can have the maximum amount of weight in that side as the wave moves across the ship.

design of the crossover pipes. Normally with the ship upright, they are going to have the same amount of fluid on each side. As the ship leans over one way the fluid in the low side is going to increase. If you can control the flow of fluid enough, you can have the maximum amount of weight in that side as the wave moves across the ship.

Ships which comply with the highest standards of a classification society recognized by the Administration are regarded as having sufficient strength for the minimum freeboards allowed under the regulations. Ships which do not comply with the highest standards of a classification society are to be assigned such increased freeboards as are determined by the assigning authority. The corresponding draft in such cases is often referred to as a scantling draft

Ships which comply with the highest standards of a classification society recognized by the Administration are regarded as having sufficient strength for the minimum freeboards allowed under the regulations. Ships which do not comply with the highest standards of a classification society are to be assigned such increased freeboards as are determined by the assigning authority. The corresponding draft in such cases is often referred to as a scantling draft Internationally, a load line is assigned and marked depending upon a subdivision and damage stability analysis of the ship under the applicable regulations of the SOLAS, 1974. Under U. S. regulations for certain ships, depending upon size or other limitations, a subdivision and damage stability examination is required if six or more passengers are carried. In no case may this subdivision load line be placed higher on a ship's side than the load line permitted under the load line regulations.

Internationally, a load line is assigned and marked depending upon a subdivision and damage stability analysis of the ship under the applicable regulations of the SOLAS, 1974. Under U. S. regulations for certain ships, depending upon size or other limitations, a subdivision and damage stability examination is required if six or more passengers are carried. In no case may this subdivision load line be placed higher on a ship's side than the load line permitted under the load line regulations.

However, there were many differences in national systems and in those systems evolving from tin foregoing international activities that were yet to be resolved.

However, there were many differences in national systems and in those systems evolving from tin foregoing international activities that were yet to be resolved.  four-week period beginning May 27, 1969.

four-week period beginning May 27, 1969.

make their rules more logical.

make their rules more logical.

submersible has an L/D of no use in the strength evaluation, a very small СB so as to be transparent to waves, and no need for sheer nor bow height since normally the weather deck may be between 9 m and 30 m above the water whether under tow or drilling. Its loading capacity is often stability limited and it is essential for survival that no wave ever impact fully on the upper structure. While all of these types can be prepared for storms of various degrees of intensity, they are all dependent on advance weather warning for survival.

submersible has an L/D of no use in the strength evaluation, a very small СB so as to be transparent to waves, and no need for sheer nor bow height since normally the weather deck may be between 9 m and 30 m above the water whether under tow or drilling. Its loading capacity is often stability limited and it is essential for survival that no wave ever impact fully on the upper structure. While all of these types can be prepared for storms of various degrees of intensity, they are all dependent on advance weather warning for survival.  Catamarans and other multi-hull ships have no direct relation to Св, while ocean mining ships and pipe-laying barges are moored at a fixed heading allowing little opportunity to utilize bow height sheer effectively by turning into a storm sea.

Catamarans and other multi-hull ships have no direct relation to Св, while ocean mining ships and pipe-laying barges are moored at a fixed heading allowing little opportunity to utilize bow height sheer effectively by turning into a storm sea.  the general safety foundation established for ship-shaped hulls by the Convention, it may be necessary to drop the definition of international voyage now used and to substitute a definition which includes operation on and exposure to the sea anywhere in the world as both standard and non-standard ships have a need for the governmental protection offered by the

the general safety foundation established for ship-shaped hulls by the Convention, it may be necessary to drop the definition of international voyage now used and to substitute a definition which includes operation on and exposure to the sea anywhere in the world as both standard and non-standard ships have a need for the governmental protection offered by the

is considered fully intact at all times and the crew of the ship is responsible for properly maintaining all closures in order that this buoyancy remains effective against the sea. Residual buoyancy for resistance to flooding is, by definition, a matter of internal compartmentation of the hull.

is considered fully intact at all times and the crew of the ship is responsible for properly maintaining all closures in order that this buoyancy remains effective against the sea. Residual buoyancy for resistance to flooding is, by definition, a matter of internal compartmentation of the hull.  Factors from previous casualties such as damage position along the length of the ship, extent of damage, existence of longitudinal bulkheads, loading and permeabilities, sea states, and finally a corroboration of formulas by model test were all used to decide the final format and coefficients for the formula replacing the SOLAS 1974 method of determining compliance. The advantages of the new method are principally that established shipbuilding techniques, such as longitudinal bulkheading, which were not creditable under SOLAS 1974 are now officially recognized in the formulas as a subdivision asset. Also, greater latitude in internal bulkhead arrangements can be accounted for.

Factors from previous casualties such as damage position along the length of the ship, extent of damage, existence of longitudinal bulkheads, loading and permeabilities, sea states, and finally a corroboration of formulas by model test were all used to decide the final format and coefficients for the formula replacing the SOLAS 1974 method of determining compliance. The advantages of the new method are principally that established shipbuilding techniques, such as longitudinal bulkheading, which were not creditable under SOLAS 1974 are now officially recognized in the formulas as a subdivision asset. Also, greater latitude in internal bulkhead arrangements can be accounted for.

Timber Freeboards

Timber Freeboards