All of us live in countries where there are laws and governing bodies telling us what we can and cannot do. However, 70% of the world is ocean, where there are no countries and, consequently, no governing bodies to tell people what is right and wrong. That is why maritime law exists.

Let us start with a hypothetical: a baby is born on a cruise ship sailing in the middle of the Atlantic Ocean. What nationality does he or she take? On the picture the coast of some fictional place in some fictional country governed by some fictional government is shown. From the white line, which is the water line at the lowest low tide, every country is allowed 12 miles of territorial waters. In the past, it used to be 3 miles – the distance a cannon could shoot off shore, but that has since changed.

Those twelve miles are the property of a country. They can do pretty much whatever they please in it and all domestic laws apply. Foreign ships are, however, sometimes allowed into these waters under the principle of innocent passage. If ships have innocent purpose – which does not include fishing, polluting, weapons practice or spying – they are allowed to pass through territorial waters of a foreign nation without permission as long as they do so quickly and without stopping on ashore.

A fire needs a chemical reaction between three elements to live. Those three elements are oxygen, heat, and fuel. By eliminating one of these elements, you can extinguish a fire. However, there are different classes of fire that require different methods of extinguishing. There are fire classes of fire as below:

- Class “A” fires are started from combustible materials, such as wood, paper, clothing, and plastics; practicing good housekeeping is the best way to prevent these fires from occurring.

- Class “B” fires are caused by flammable liquids such as gasoline, petroleum oil, and paint. However, they can also be started by flammable gases like propane and butane. These fires are common in areas like the engine room. engine room.

- Class “C” fires involve energized electrical equipment, such as transformers, motors, and other electrical equipment commonly found onboard ship.

- Class “D” fires occur when a combustible metal catches fire. Aluminum, magnesium, and other metals can catch fire. These fires are extremely hot and difficult to extinguish, as they create their own oxygen. A special extinguishing agent must be used that interferes with the chemical reaction.

- Class “K” fires typically occur in the galley with cooking oils and greases, like animal and vegetable fans.

All these fires are fueled by different combustibles and often require different types of extinguishing agents. One of the most widely used extinguishers is the multi-purpose dry chemical extinguisher. This agent creates a barrier between the oxygen and the fuel. These extinguishers are used on class “A”, “B” and “C” fires. While the dry chemical can be used on electrical fire, it will often cause damage to electrical components and circuitry. In this case, CO2 is a better choice.

Ordinary dry chemical extinguishers work by interrupting the chemical reaction and should only be used on class “B” and “C” fires.

Water and foam extinguishers are used for fighting small class “A” fires. These extinguishers and hoses take away the heat element with the water, and the foam separates the oxygen from the other elements. Water and foam extinguishers are used for fighting small class “A” fires. These extinguishers and hoses take away the heat element with the water, and the foam separates the oxygen from the other elements.

Water hoses are used in the event of class “A” or class “C” fires. They are also effective when fighting petroleum fires. In other fires, the stream could spread the flammable liquid or create a shock hazard.

Carbon dioxide extinguishers take the oxygen element out of the fire and then remove the heat with the cold discharge. CO2 is heavier than air and will therefore displace the air at the base of the fire where combustion occurs. These extinguishers shall only be used on class “B” and “C” fires. CO2 extinguishers are more effective in close spaces as opposed to the open areas such as the deck where the gas can be dispersed.

The multi-purpose cartridge extinguishers, like the stored pressure extinguishers, are effective in fighting class “A”, “B” and “C” fires by creating a barrier between oxygen and fuel.

Clean agent extinguishers extinguish class “B” and “C” fires. Larger clean agent extinguishers can also be used on “A”, “B” and “C” fires. Clean agent extinguishers include halon and halon-carbon agents and extinguish fires by interrupting chemical reaction of the fire triangle.

To fight a class “D” combustible metal fire, you should use the dry powder not dry chemical extinguisher. This special fire extinguishing agent breaks the fire chain at the molecular level, preventing combusting.

To fight class “K” fire in a galley, you will have to use the wet chemical agent which removes heat from the fires and creates barrier between the oxygen and the fuel, preventing re-ignition.

Make sure that the extinguishers are placed in the correct areas and are not covered in any way. Instruction on how to operate the extinguisher must be facing out.

Fire extinguishers are required to be visually examined every monthly and serviced annually.

In addition to fire extinguishers, a ship will most probably have a built-in fire suppression system, and its components are fire hoses, nozzles, piping, and fire pumps. In the engine room one will also find built-in sprinkler systems, along with semi-portable CO2 fire extinguishers. suppression system, and its components are fire hoses, nozzles, piping, and fire pumps. In the engine room one will also find built-in sprinkler systems, along with semi-portable CO2 fire extinguishers.

Older steamships may have steam smothering lines in the cargo spaces.

Detection sensors are installed throughout the ship, and will sound an alarm in the presence of smoke, fumes, steam, or heat.

There will be a master alarm panel installed on the navigation bridge, and, possibly, in the engine control room. When a sensor is triggered, a panel will show the location of the event, allowing a rapid response to the possible fire.

We all know that seafaring is as such a very dangerous enterprise, since there are so many threats that the seafarers of today have to face every single day. In addition to the storms and hurricanes, pirates, hijacking and other unpleasant events, one of the most terrific hazards is still the destructive force of shipboard fires.

Knowing that any mistake can cause catastrophic fire means that all of the crew members of your vessel shall be provided with proper training and follow proper policies and procedures as necessary and at all times. Good vessel construction, housekeeping and maintenance, following the established safety procedures, and keeping shipboard fixed and portable fire-fighting systems fully operational are all important for preventing fires. Your firefighting training can one day save the ship, cargo, and the lives of your fellow crew members and passengers.

Let us spend some time discussing the very essential fire prevention aspects, commonly used fire extinguishing agents and systems, as well as the personal protective equipment (PPE) that are required for all those involved in the firefighting activities, and, of course, fighting the fire itself. It goes without saying that the provisions of the Safety Management System Manual shall prevail at all times. systems, as well as the personal protective equipment (PPE) that are required for all those involved in the firefighting activities, and, of course, fighting the fire itself. It goes without saying that the provisions of the Safety Management System Manual shall prevail at all times.

Maintaining a safe environment is considered absolutely crucial in fire prevention, and this means constant vigilance from all crew members, demonstrated at all times. They shall always ask themselves questions like - are there any potential hazards from the work that you are performing, such as sparks or ignition, are the proper procedures for welding, cutting or hot work followed, including issuance of the hot work permit, etc.

Have a close look around your work area – are there any combustible materials lying around, such as faulty electrical installations, poorly insulated exhausts, or fuel and oil leaks? These may see like small issues, but, if left untreated, they could lead to disaster. The practice shows that many fires can be avoided by timely checking the equipment for damaged wires, faulty electrical connections, and putting oily rags into a sealed container. Make sure that you never place combustible materials near a heat source, like exhaust pipes or heaters. The engine room is deservedly treated as a home for many hazards, such as ruptured lines and pipes, loose fittings, and oil leaking from equipment. Immediately repair any leaks.

Another area of the vessel where chance of the fire is high, is the galley. The galley can never be left unattended while cooking.  By maintaining a clean galley, grease accumulation will not be present to fuel the fire. Ensure the exhaust fans and ductwork are cleaned regularly as these are the major sources of galley fires. By maintaining a clean galley, grease accumulation will not be present to fuel the fire. Ensure the exhaust fans and ductwork are cleaned regularly as these are the major sources of galley fires.

Here are few things to look for in the galley:

- Accumulation of grease and oil on cooking appliances

- Grease or soot in the fans and exhaust

- Rags and garbage are disposed of in the correct containers.

In the next article, we will have a look at the fire extinguishing agents available today to the seafarers onboard their vessels.

Fire prevention is your first line of defense against the fire. However, if a fire does start, firefighters will need the right personal protective equipment to improve their chance of survival. It is vital that you learn the location of this equipment and understand how to quickly and properly put it on.

Ships may be equipped with the firefighter bunker suits increasing your protection of the human from flames, radiant heat and steam, allowing you to get near to the source of the fire. The bunker gear consists of turnout coat and pads. Protect yourself further with a firefighting helmet, gloves and rubber firefighting boots.

Your ships are equipped with the self-contained breathing apparatus, or SCBA units. Before using them, make sure that you have been fit tested and properly trained to use the SCBA suits. The SCBA shall carry at least thirty minutes of air on your normal circumstances. have been fit tested and properly trained to use the SCBA suits. The SCBA shall carry at least thirty minutes of air on your normal circumstances.

An emergency escape breathing device, or EEBD, is designed to help crew escape from the smoky compartment and contains enough oxygen to last at least ten minutes. They are intended strictly for escape purposes and should not been used in firefighting.

Many times, when dealing with small fires, crew members will not have time to change into the protective clothing. Be aware of your clothing limitations when preparing to fight the fire. And always remember that fires are much safer and easier to fight at their early stages.

Every now and then we hear yet another story about a nighttime collision at sea, maybe between a ferry and a yacht or even between two large ships. Either way, the same question always comes up – why did not they see each other?

Sure, if it is nighttime, it is harder to see things, as you must have noticed it yourself when driving at night, you need headlights to stand a chance of seeing anything. Yet, when you look at a ship at night, they do not have headlights.

But why? If the headlights work fine for car, why not for ships? Well, think about what a headlight actually is. It is just a source of light, designed to emit photons which can bounce off objects and return to your eyes. Your brain then interprets them and tells you what you are seeing.

Simple enough but you need a light powerful enough to illuminate the area you are looking at. The power from the light is dispersed across the full width of its beam. Then, when the light hits an object, small bit of its beam that hits the object is reflected back, but it is again dispersed, meaning that only a tiny fraction of the original light gets back to you.

That is fine in a car, you want to narrow the area right ahead of you extending out far enough that you can take action to avoid the things that you see. Even at motorway speeds around 100 meters should be enough. You are probably starting to see where I am going with this.

With a ship 100 meters may not be enough to see your own bow, let alone to see far enough ahead to take any action. A large cargo ship, for example, needs more than a mile to stop. With two such vessels approaching each other, you are looking at needing at least two miles visibility to take action in time. You know how bright a car’s headlight is. Just think how much brighter a ship’s headlight would need to be to have the same effect!

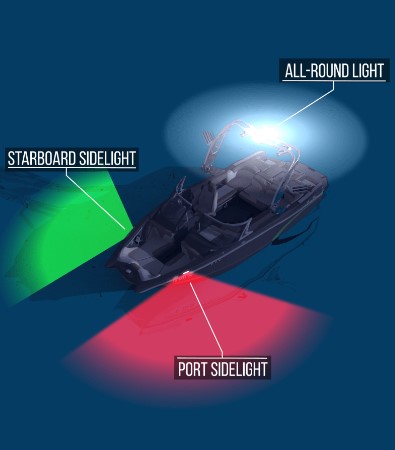

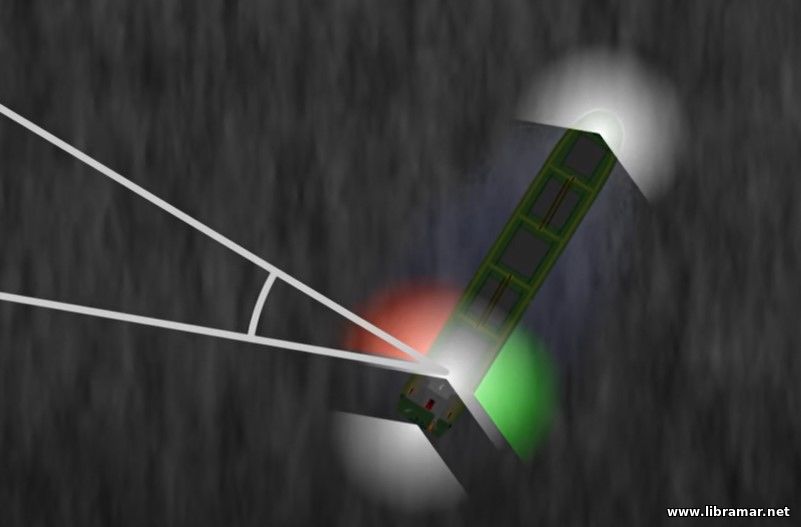

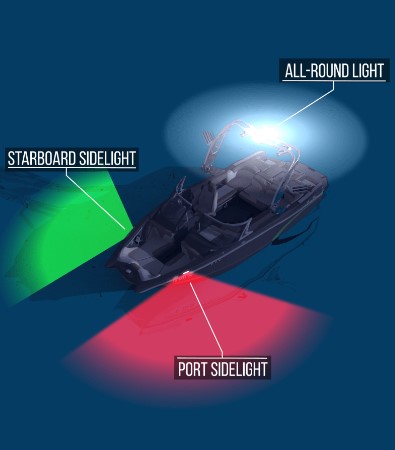

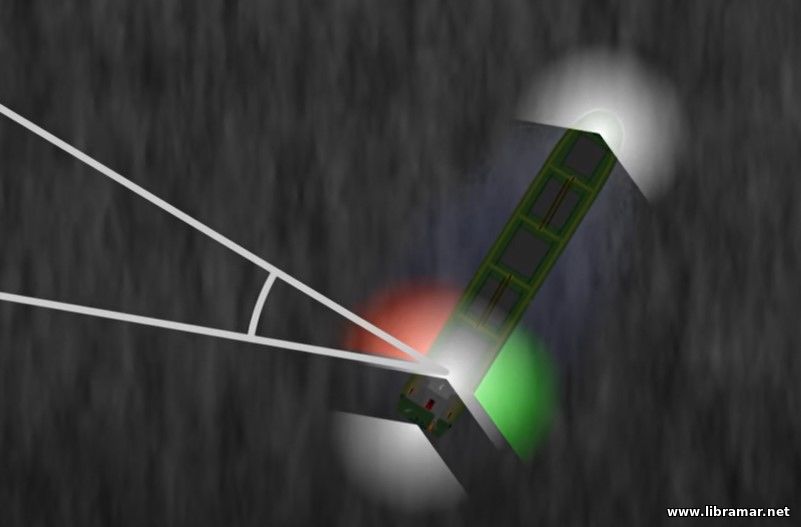

Imagine two ships approaching each other at night. We have already established that they do not use headlights to see each other. So, what do they use? Well, they still use lights, but they are called navigation or nav lights instead. Every seaworthy vessel is fitted with nav lights the idea is that they are arranged in a standardized distinctive way so that other vessels can not only see you, but also identify how you are moving. As nav lights are fitted to the target vessel, their power only needs to be sufficient to be seen by other vessels.

If you have a light fitted as shown on the picture, rather than just relying on a tiny portion of reflected light, you can see how much easier it will be to see compared to using a headlight. much easier it will be to see compared to using a headlight.

But what about identifying their movement? Let us take this cargo ship as an example. She would show two masthead lights, the aft one being higher than the forward one. These immediately tell other ships in which direction she is moving. But she also shows sidelights. These are the colored lights that you probably know about – red for port and green for starboard. Again, it reinforces, which way she is traveling.

But the lights can tell us even more than that. If we are looking at the vessel’s port side and she turns towards us – as the masthead lights come in line, you can start to see both sidelights. You know the other vessel is heading straight for you. Take the look from above and you can see that the only angle where you would see all those lights is from right ahead. The observant among you will spot that these lights do not go all the way around either. Instead, we have a single white light filling in the sector of the stern, as shown on the picture. What this means is that if you spot a single white light, one of the things it could be is a power-driven vessel viewed from a stern.

If she turns a bit you can come on the cusp of viewing her sidelights and mast headlights, too. Looking from above, the only thing where this is possible, is along the white line shown – it is two points of 22.5 degrees above the beam – the very definition of overtaking we took straight from COLREGs.

Of course, we just looked at a power-driven vessel here but there are countless variations on this arrangement. You can  add extra mast headlights to indicate you are towing or show only side lights to indicate you are sailing. You can even modify your status by adding two all-round red lights to show you are not under command, or three all-round red lights to show you are aground or make the middle one white to show that you are restricted in your ability to maneuver. add extra mast headlights to indicate you are towing or show only side lights to indicate you are sailing. You can even modify your status by adding two all-round red lights to show you are not under command, or three all-round red lights to show you are aground or make the middle one white to show that you are restricted in your ability to maneuver.

See, nav lights tell you so much more that headlights ever could. They accomplish the basics making the vessel show up against the dark sky. But, in addition, they allow you to identify the vessel type, work out its aspect, and see which way she is moving – all vital information when it comes to applying the collision regulations, and working out which of you needs to give way to the other.

It is very important to understand the importance of the shipboard communications at all levels in order to achieve safe and efficient ship operation. What is communication? Here is one possible definition – transferring signals and messages from one person to another with the purpose of creating an understanding, a particular meaning or a certain reaction from the other person. If no reaction is received, we are talking about one-way communication.

According to statistics, as much as 70-80% of incidents and accidents at sea can be traced back to some kind of communication problem including those between personnel on the bridge because of different culture, native language, age, experience etc., between bridge and engine personnel, ship and tugs, ship and VTS, ship and ship owner/operator, ship and authorities.

Have you noticed how boats, both large and small, tend to be painted a different color under the water? Most often, it is red but actually nowadays you can get any color you like. The reason for it goes back to the earliest days of sailing ships. Back in those days wooden sailing ships would slowly plot around the world. A combination of their slow speed and rough hull made them an ideal breeding ground for underwater growth. Just take a look under a pier and you will see the sort of marine growth these ships used to suffer. We are talking barnacles, worms, seaweed, and things like that, so that is the issue.

Well, all of these things have negative impacts on ships over time. You get the obvious of things like damage to the hull itself due to worms and the actual growth; then you get issues like the additional weight that they have to carry around and reduction in maximum speed due to the extra drag. Of course, on sailing vessels that drag-on weight would impact their ability to sail upwind which would yet further reduce their efficiency. What you need is a way to stop marine life from growing on the bottom of the hull and this is where antifouling comes in. this is where antifouling comes in.

Antifouling is just a system designed to reduce fouling by animal and plant life on the underwater sections of a boat or a ship. Early solutions were to place copper sheets on the hulls of ships. The “Cutty Sark” is a great example of this. The primary purpose of the copper sheets was actually to stop worms eating their way through wooden hulls. A secondary benefit is that the copper would reduce the growth of plant life.

Of course, as wooden hulls were replaced by iron, worm issue did reduce but they have never been eliminated. Just look at the leisure industry today and you will still see a plenty of wooden hulls around, and of course regardless of its construction materials we still have the same old issue of drag caused by the growth of plant life is probably more important now to keep that under control, considering the costs of fuel and efficiency savings on long passages.

We still need antifouling to stop a combination of worms, barnacles and weed from growing on the underside of the hulls but instead of using the old technique of copper sheets we now use a form of paint. The subject paint works on the same principle and actually still uses copper as a biocide though it is mostly cuprous oxide mixed with the paint rather than copper sheets.

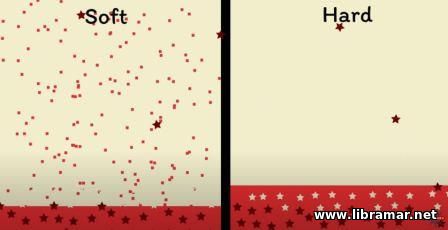

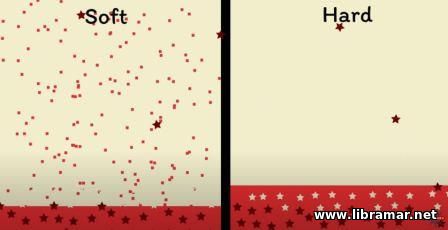

It is the natural red color of those copper oxides that has led to the traditional red color of antifouling. Modern antifouling systems can be broken into two broad categories – hard and soft. Soft coatings are designed to wear off over time continuously exposing  fresh biocides as the outer layer of the paint wears off. Hard coatings, on the other hand, are designed to be lot more durable. They are meant to last a lot longer. As the biocides are released the durable layer of paint remains but the biocides contained in the outermost layer do get used up. fresh biocides as the outer layer of the paint wears off. Hard coatings, on the other hand, are designed to be lot more durable. They are meant to last a lot longer. As the biocides are released the durable layer of paint remains but the biocides contained in the outermost layer do get used up.

Both systems work on the same principle. They gradually release biocides commonly based on the chemical element copper. The difference is that the soft coatings allow the paint to flake off as well. As you can imagine, there are environmental considerations – antifouling releases biocides and possibly paint into the environment. That is one reason a lot of ports do not allow cleaning the hulls. They do not want the extra dose of biocides and paint released by the rubbing process.

One of the other options is to use the normal hardware and paint on the other side of the hull but that will result in a lot of aquatic growth. That is fine on a small boat that you can pull out of the water and clean quite often, but is not so great on a container ship running around the world. What would happen if, for example, container ship picked some weed in Asia and carried it into the Baltic Sea where it takes hold and overtakes some of the native species? Similar things have happened and do actually continue to happen though it is not so much from hull growth because antifouling is more of an issue for the ballast water.

So, aside from just using no antifouling, what could you do? There is a talk of systems that slowly use some sort of jelly from the hull. The theory is that as the growth attaches to the hull, the jelly seeps off and takes the growth with it. There are also some silicon based paints that make it hard for barnacles to stick to the hull. Unfortunately, these do not actually stop the growth but it makes it easier to clean off.

As said above, most ports do not allow cleaning anyway not only because of the historical antifouling issues but also they do not want to clean off species that are not native to the harbor itself. The last thing they want is to be overcome by some sort of invasive weed from the other side of the world.

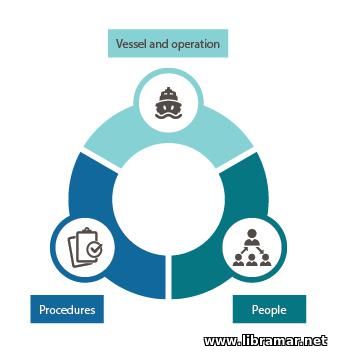

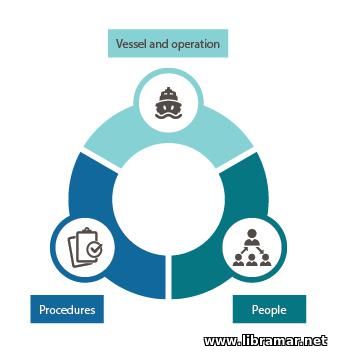

Safety must be essential factor in all ship operations. Ship owners need to make a profit, but the best way to do that today is by operating safely. The senior management team on the ship needs to put the health, safety, and security of their crew above everything else. To achieve that, safety must be managed effectively.

The ISM Code makes safety management essential. But safety management makes good sense in both human and commercial terms. For all shipping companies, a history of shipping incidents and accidents damages their reputation and leads to the loss of business and further financial consequences.

It may seem that accidents happen at random, but the researches show that there appears to be a relationship between near misses and serious accidents. The more near misses, or hazardous occurrences that happen, the more minor or serious accidents occur. Proper evaluation of a near miss or hazardous occurrence reports and making appropriate changes in procedures will reduce accidents and contribute in managing safety on board.

There are many components to successful safety management and obvious one is good training and familiarization with the company’s safety management systems. Another one is proper maintenance, including making sure that all maintenance is correctly carried out and logged. Motivation and leadership is also vital. If safety matters to the senior officers, everyone on board will notice that; they will then make safety a high priority in their own activities.

This leadership is an essential part of another component – the development of the safety culture. The senior officers must make  it clear that they are committed to the company’s safety procedures for it is their attitude to safety that determines the safety culture of the ship. it clear that they are committed to the company’s safety procedures for it is their attitude to safety that determines the safety culture of the ship.

Finally, there are the safety management procedures themselves – these shall be developed by the shore office in consultation with the shipboard management team based on their experience, risk assessment, and legal requirements. But the shore office’s responsibility does not end with creating good working procedures. They also have a responsibility to employ personnel of a suitable standard both at sea and ashore.

Most important of all, there shall be open communication and trust between the ship and the shore. The Designated Person Ashore under the ISM Code must ensure that everyone ashore and on board works together to manage safety. For safety management systems to be effective, they must be regularly reviewed to ensure continuous improvement.

Standards must be established and then implemented. The progress of this implementation must be followed and measured so compliance can be checked. The situation must be reviewed and changes made if the objectives have not been met.

|

engine room.

engine room.  Water and foam extinguishers are used for fighting small class “A” fires. These extinguishers and hoses take away the heat element with the water, and the foam separates the oxygen from the other elements.

Water and foam extinguishers are used for fighting small class “A” fires. These extinguishers and hoses take away the heat element with the water, and the foam separates the oxygen from the other elements. suppression system, and its components are fire hoses, nozzles, piping, and fire pumps. In the engine room one will also find built-in sprinkler systems, along with semi-portable CO2 fire extinguishers.

suppression system, and its components are fire hoses, nozzles, piping, and fire pumps. In the engine room one will also find built-in sprinkler systems, along with semi-portable CO2 fire extinguishers.

systems, as well as the

systems, as well as the  By maintaining a clean galley, grease accumulation will not be present to fuel the fire. Ensure the exhaust fans and ductwork are cleaned regularly as these are the major sources of galley fires.

By maintaining a clean galley, grease accumulation will not be present to fuel the fire. Ensure the exhaust fans and ductwork are cleaned regularly as these are the major sources of galley fires.

have been fit tested and properly trained to use the SCBA suits. The SCBA shall carry at least thirty minutes of air on your normal circumstances.

have been fit tested and properly trained to use the SCBA suits. The SCBA shall carry at least thirty minutes of air on your normal circumstances.

much easier it will be to see compared to using a headlight.

much easier it will be to see compared to using a headlight. add extra mast headlights to indicate you are towing or show only side lights to indicate you are sailing. You can even modify your status by adding two all-round red lights to show you are not under command, or three all-round red lights to show you are aground or make the middle one white to show that you are restricted in your ability to maneuver.

add extra mast headlights to indicate you are towing or show only side lights to indicate you are sailing. You can even modify your status by adding two all-round red lights to show you are not under command, or three all-round red lights to show you are aground or make the middle one white to show that you are restricted in your ability to maneuver.

this is where

this is where  fresh biocides as the outer layer of the paint wears off. Hard coatings, on the other hand, are designed to be lot more durable. They are meant to last a lot longer. As the biocides are released the durable layer of paint remains but the biocides contained in the outermost layer do get used up.

fresh biocides as the outer layer of the paint wears off. Hard coatings, on the other hand, are designed to be lot more durable. They are meant to last a lot longer. As the biocides are released the durable layer of paint remains but the biocides contained in the outermost layer do get used up.

it clear that they are committed to the company’s safety procedures for it is their attitude to safety that determines the safety culture of the ship.

it clear that they are committed to the company’s safety procedures for it is their attitude to safety that determines the safety culture of the ship.