Oil, fuels, lubricants, chemicals are the lifeblood of our modern industrial world. The cargo is pressurized but volatile. Within the hull of the ship, each tank is sealed to maintain the cargo quality and protect the crew, the vessel and the environment. But the cargo is also dynamic, its volume changes all the time, very obviously at loading and discharging, and less obviously through temperature changes and vaporization.

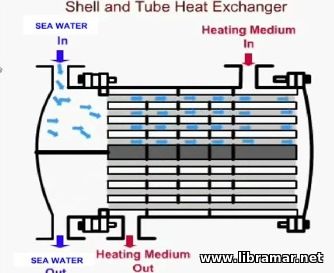

The volume of the tank is fixed, so changes in volume of liquids and gases within the tank must be accommodated, or they will translate into changes in pressure. Tank bulkheads are thin; they are designed to operate within tight parameters. Typically at commissioning they are tested with pressures of around a quarter-bar and a vacuum of less than 1/10 bar. The forces are massive, enough to disturb frames, bulkheads and decks, causing catastrophic failures, explosions, fire and pollution.

This video sheds light on the important aspects of handling pressures within the cargo tanks of the vessels. The information and knowledge gained when watching this video lesson carefully, will be of great practical use for the people working on board and can eventually result in prevention of the negative consequences caused by either under- or over-pressurization of cargo tanks.